Unlocking Innovations in Prototype Aluminum Casting: Key Advantages and Industry Insights

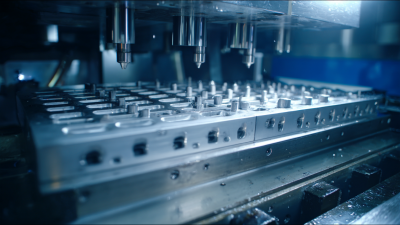

In recent years, the demand for Prototype Aluminum Casting has surged, driven by its critical role in the rapid prototyping and manufacturing sectors. According to industry reports, the global aluminum casting market is projected to reach USD 78 billion by 2027, with prototype casting accounting for a significant segment due to its versatility and efficiency. The adoption of advanced casting technologies, such as 3D printing and CNC machining, has further enhanced the capabilities of prototype aluminum casting, enabling quicker turnaround times and improved material properties. This article explores the key advantages of prototype aluminum casting, such as reduced time-to-market and cost-effectiveness, while also highlighting industry insights that underscore its transformative impact on product development and innovation. As manufacturers seek to stay competitive in an ever-evolving marketplace, understanding the nuances of prototype aluminum casting becomes essential for unlocking new innovations and optimizing production processes.

Read more »

By:Madeline - October 27, 2025

By:Madeline - October 27, 2025

By:Madeline - October 25, 2025

By:Madeline - October 25, 2025

By:Sophia - October 24, 2025

By:Sophia - October 24, 2025

By:Emily - October 21, 2025

By:Emily - October 21, 2025

By:Sophia - October 19, 2025

By:Sophia - October 19, 2025

By:Sophia - October 16, 2025

By:Sophia - October 16, 2025

By:Emily - October 13, 2025

By:Emily - October 13, 2025

By:Emily - October 12, 2025

By:Emily - October 12, 2025

By:Sophia - October 11, 2025

By:Sophia - October 11, 2025

By:Emily - October 8, 2025

By:Emily - October 8, 2025

By:Emily - October 5, 2025

By:Emily - October 5, 2025

By:Sophia - October 2, 2025

By:Sophia - October 2, 2025

By:Madeline - September 30, 2025

By:Madeline - September 30, 2025

By:Madeline - September 28, 2025

By:Madeline - September 28, 2025

By:Sophia - September 25, 2025

By:Sophia - September 25, 2025