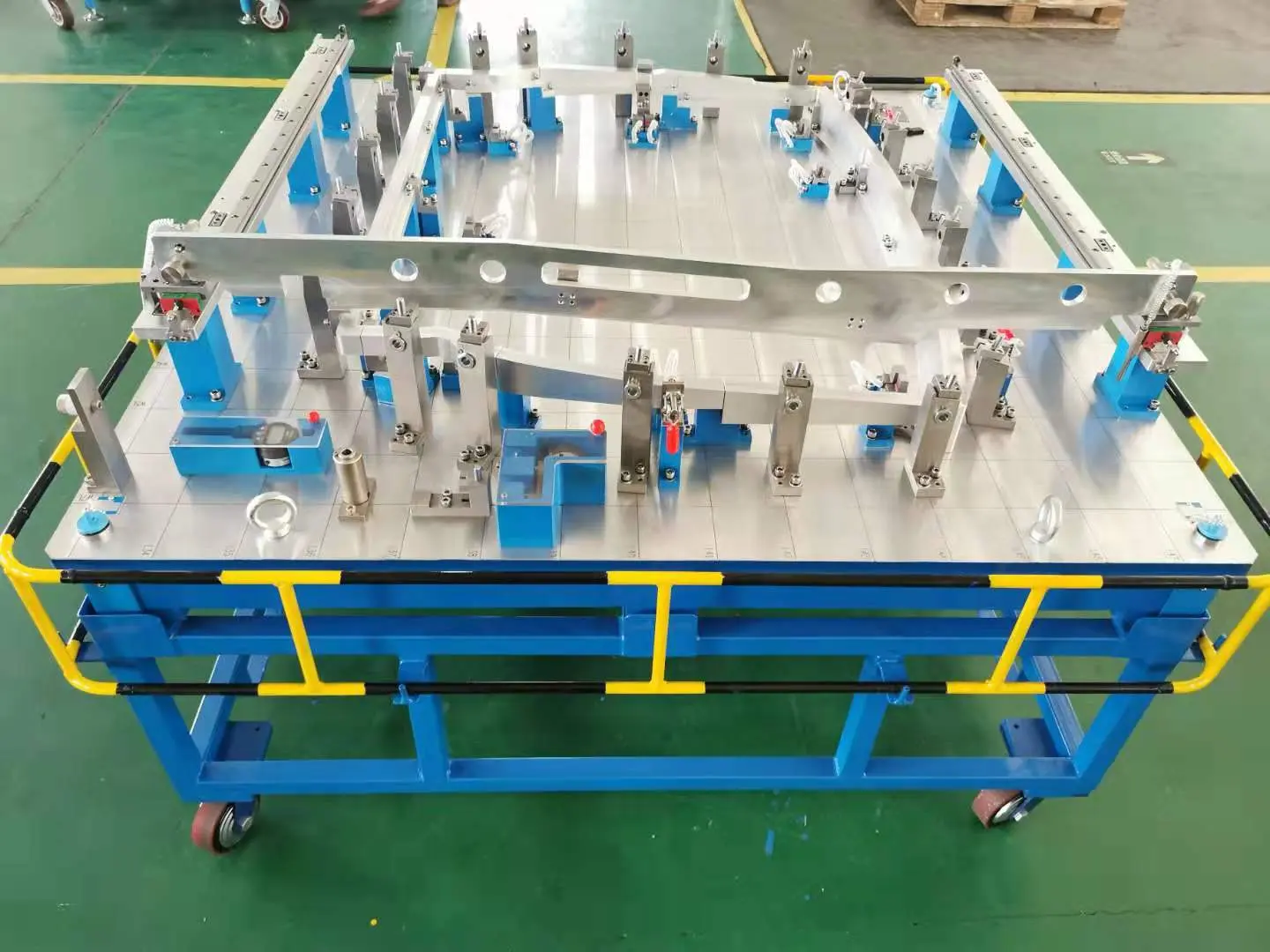

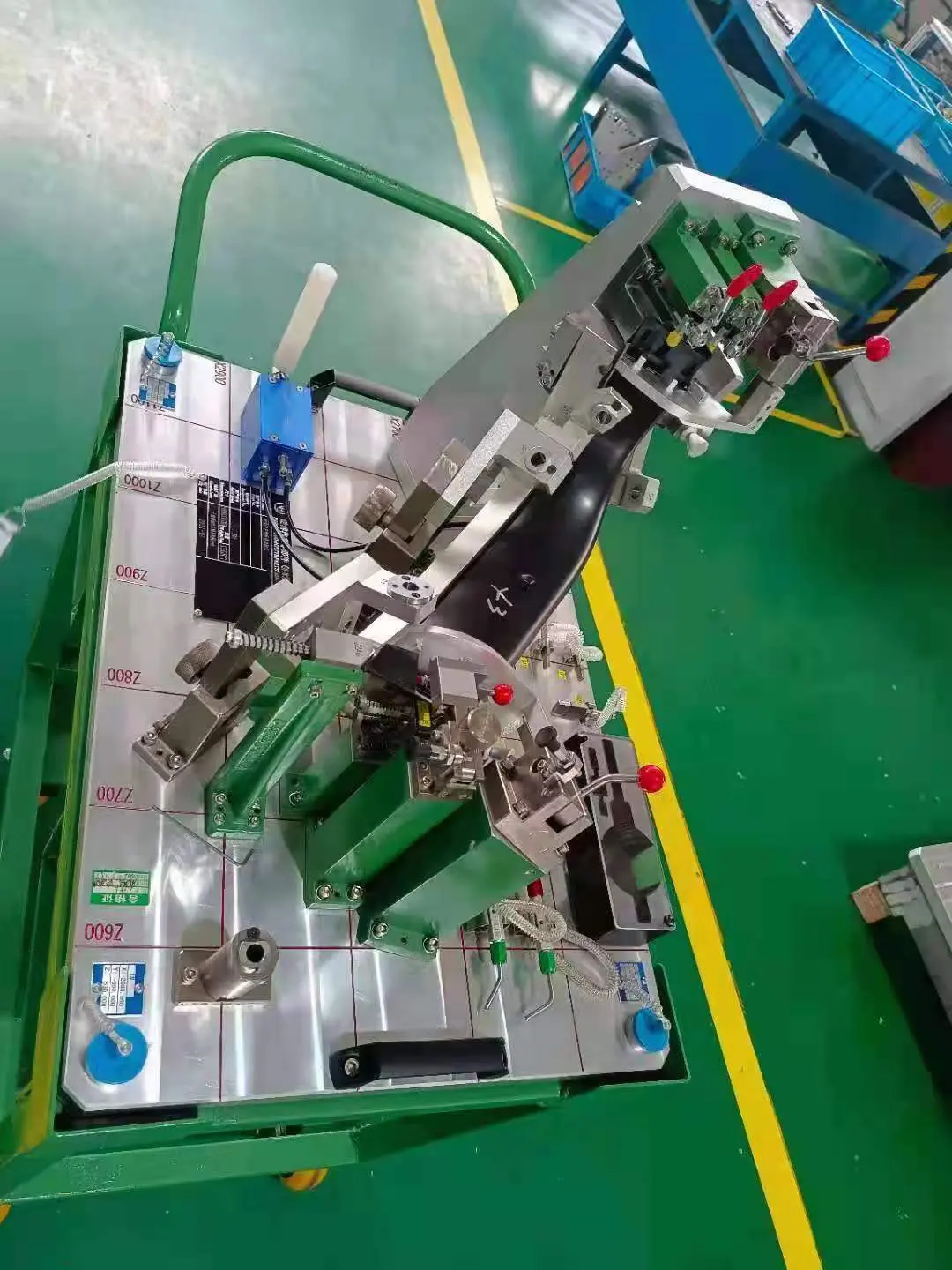

The importance of inspection fixtures

Inspection fixtures are tools specifically designed to verify the dimensional accuracy and functionality of automotive parts. They are used in conjunction with coordinate measuring machines (CMMs) and other inspection equipment to ensure parts meet specified tolerances and design requirements. By using inspection fixtures, manufacturers can identify any deviations or defects in parts, allowing them to make necessary adjustments and improvements before the product reaches the market.

Inspection fixtures are tools specifically designed to verify the dimensional accuracy and functionality of automotive parts. They are used in conjunction with coordinate measuring machines (CMMs) and other inspection equipment to ensure parts meet specified tolerances and design requirements. By using inspection fixtures, manufacturers can identify any deviations or defects in parts, allowing them to make necessary adjustments and improvements before the product reaches the market.

One of the main benefits of using inspection fixtures is the ability to simplify the inspection process. Designed to be extremely precise and efficient, these tools can measure multiple parts quickly and accurately. Not only does this save time, it also reduces the possibility of human error, ensuring the inspection process is thoroughly reliable. As a result, manufacturers can be confident in the quality of their products and maintain high levels of customer satisfaction.

In addition to improving the inspection process, inspection fixtures also play a vital role in ensuring the overall safety and performance of automotive parts. By accurately verifying component dimensions and functionality, these tools help prevent the production of defective or substandard parts. This is especially important in the automotive industry, where even the smallest deviations in part dimensions can lead to serious safety hazards and performance issues. With the help of inspection devices, manufacturers can maintain the highest quality and reliability standards of their products.

Additionally, inspection fixtures help save costs and increase the efficiency of the manufacturing process. By identifying and resolving any issues early, manufacturers can avoid costly rework and scrap, ultimately reducing production expenses. Additionally, using inspection fixtures helps minimize the risk of product recalls and warranty claims, saving time and resources in the long run. This not only benefits the manufacturer but also improves the overall reputation and credibility of their brand in the market.

To sum up, inspection tools are indispensable tools in the field of automobile inspection. Their ability to ensure accuracy, simplify inspection processes, enhance safety and save costs makes them an essential component of quality control in the automotive industry. As manufacturers continue to prioritize the production of high-quality and reliable automotive parts, inspection fixtures will continue to play a vital role in maintaining these standards. With their proven benefits and impact on product quality, inspection fixtures are a valuable investment for any manufacturer seeking to maintain a competitive edge in the market.