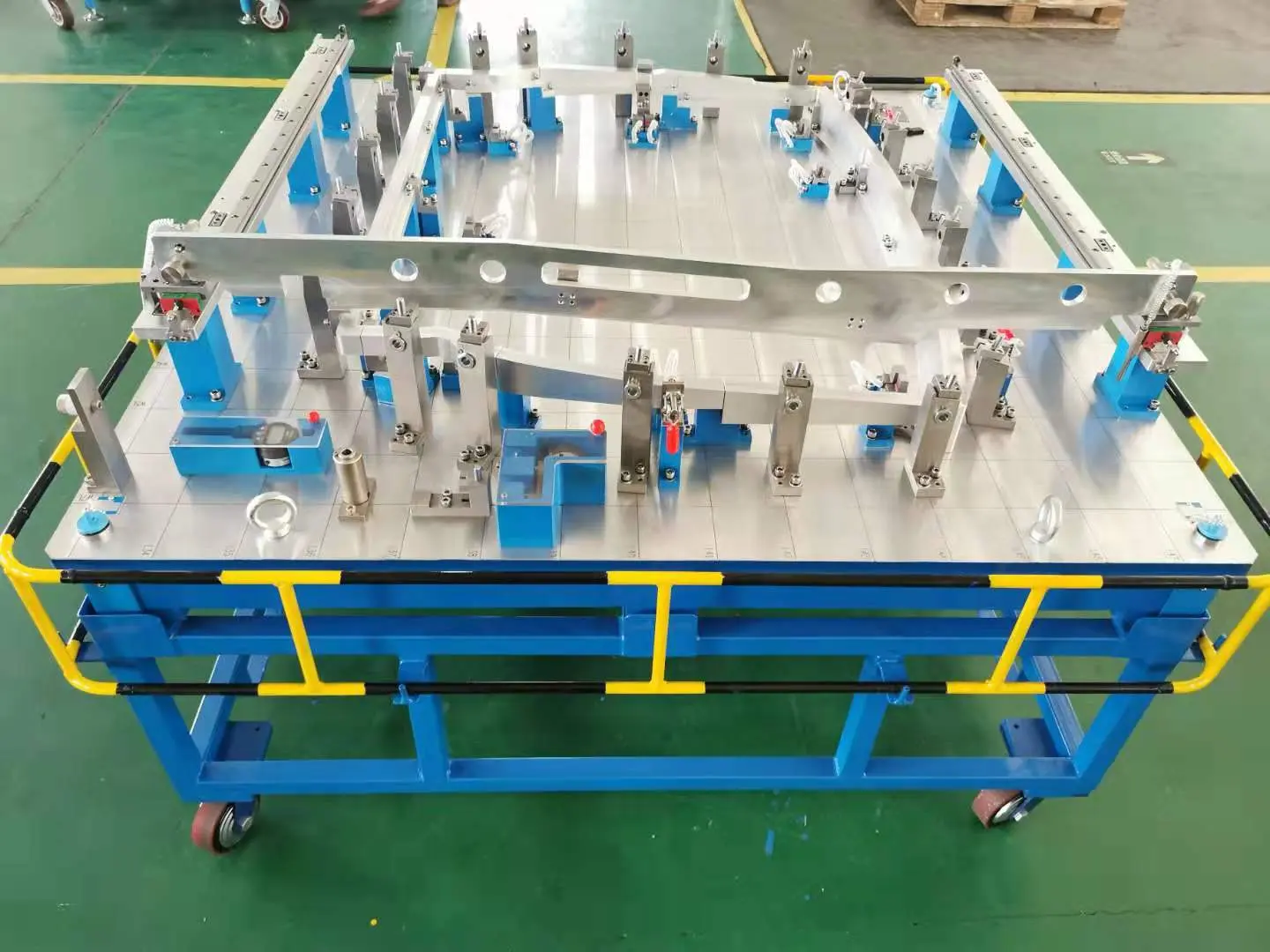

The Importance of Inspection Devices for Engine Cover Manufacturing

One of the main benefits of using inspection fixtures in hood manufacturing is the ability to ensure precise dimensional accuracy. The hood is an important part of the car body and any deviation from the specified dimensions may cause fit and function issues. Inspection devices allow manufacturers to verify that the hood meets exact specifications, ensuring a perfect fit when installed on the vehicle. This level of precision is critical to maintaining the overall quality and performance of the car.

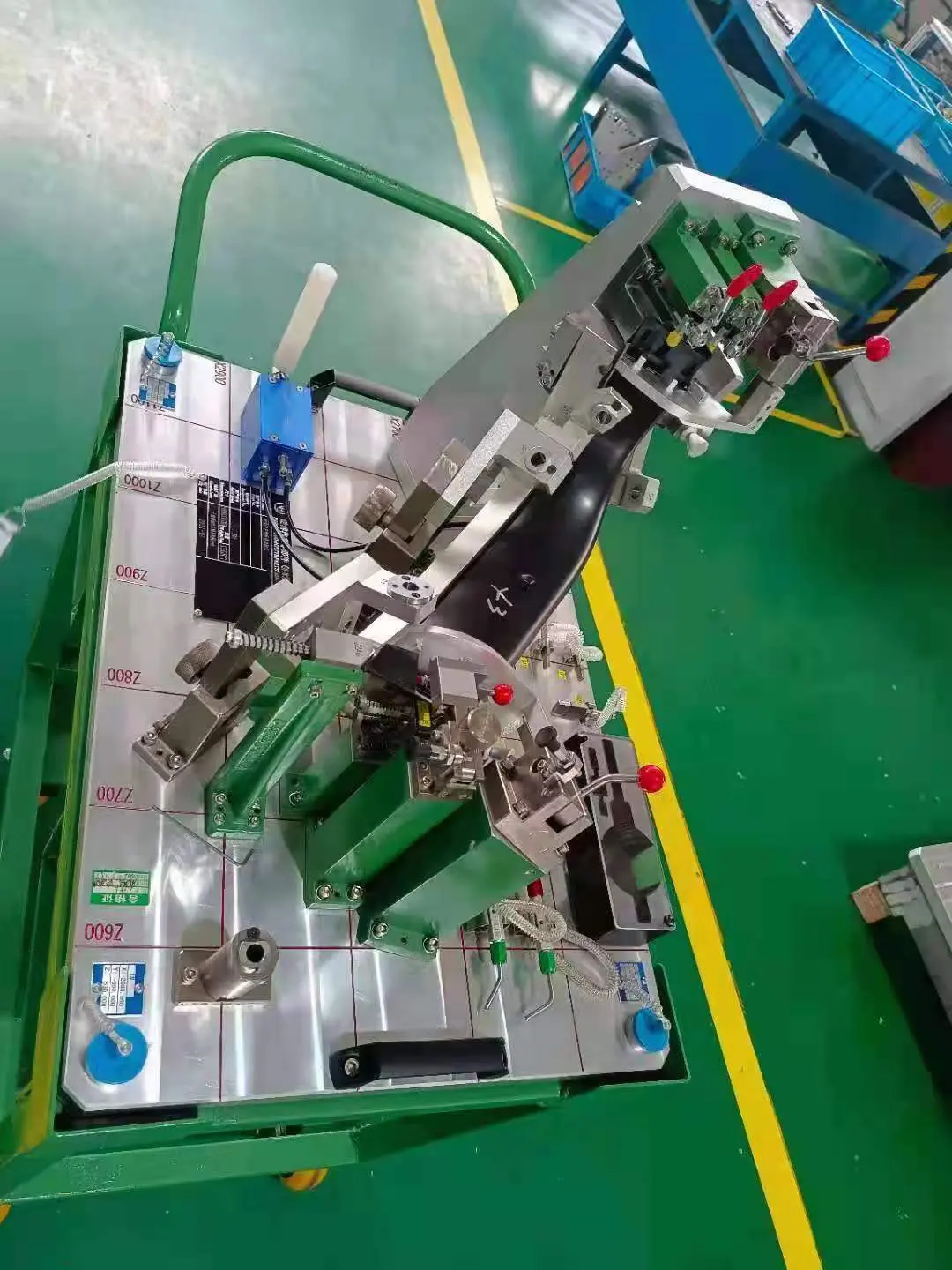

In addition to dimensional accuracy, inspection devices play a vital role in ensuring the structural integrity of hoods. Shields are subject to various stresses and forces during operation, so they must be able to withstand these conditions without compromising safety or performance. Inspection devices allow manufacturers to test the structural integrity of hoods to ensure they meet required strength and durability standards. This helps prevent issues like warping, cracking, or deformation that can compromise the safety and functionality of your hood.

Additionally, inspecting fixtures helps maintain consistency and quality throughout the manufacturing process. By using inspection devices at all stages of production, manufacturers can detect and resolve any issues or deviations early before they affect the final product. This proactive approach helps minimize rework and scrap, ultimately saving costs and increasing efficiency. Additionally, the use of inspection jigs helps standardize the manufacturing process, ensuring that every hood produced meets the same high-quality standards.

Another important aspect of inspection jigs in hood manufacturing is their role in promoting efficient, accurate assembly. The hood is made up of various parts that need to fit together seamlessly, and inspection jigs are used to verify the alignment and fit of these parts. By using inspection devices to verify the assembly process, manufacturers can ensure that all components fit together correctly, producing an engine cover that performs as expected. Not only does this help improve the overall quality of the hood, it also helps simplify the assembly process, saving time and resources.

In summary, inspection jigs are an indispensable tool in hood manufacturing and play a key role in ensuring dimensional accuracy, structural integrity, consistency and efficient assembly. By using inspection devices throughout the manufacturing process, manufacturers can adhere to the highest quality standards, producing hoods that meet exact specifications and perform flawlessly when installed on the vehicle. As the automotive industry's requirements for precision and reliability continue to increase, inspection fixtures will continue to be an important part of engine cover manufacturing, helping to produce high-quality, reliable automotive engine covers.