The Importance of Checking Fixtures for C-Pillar in Automotive Manufacturing

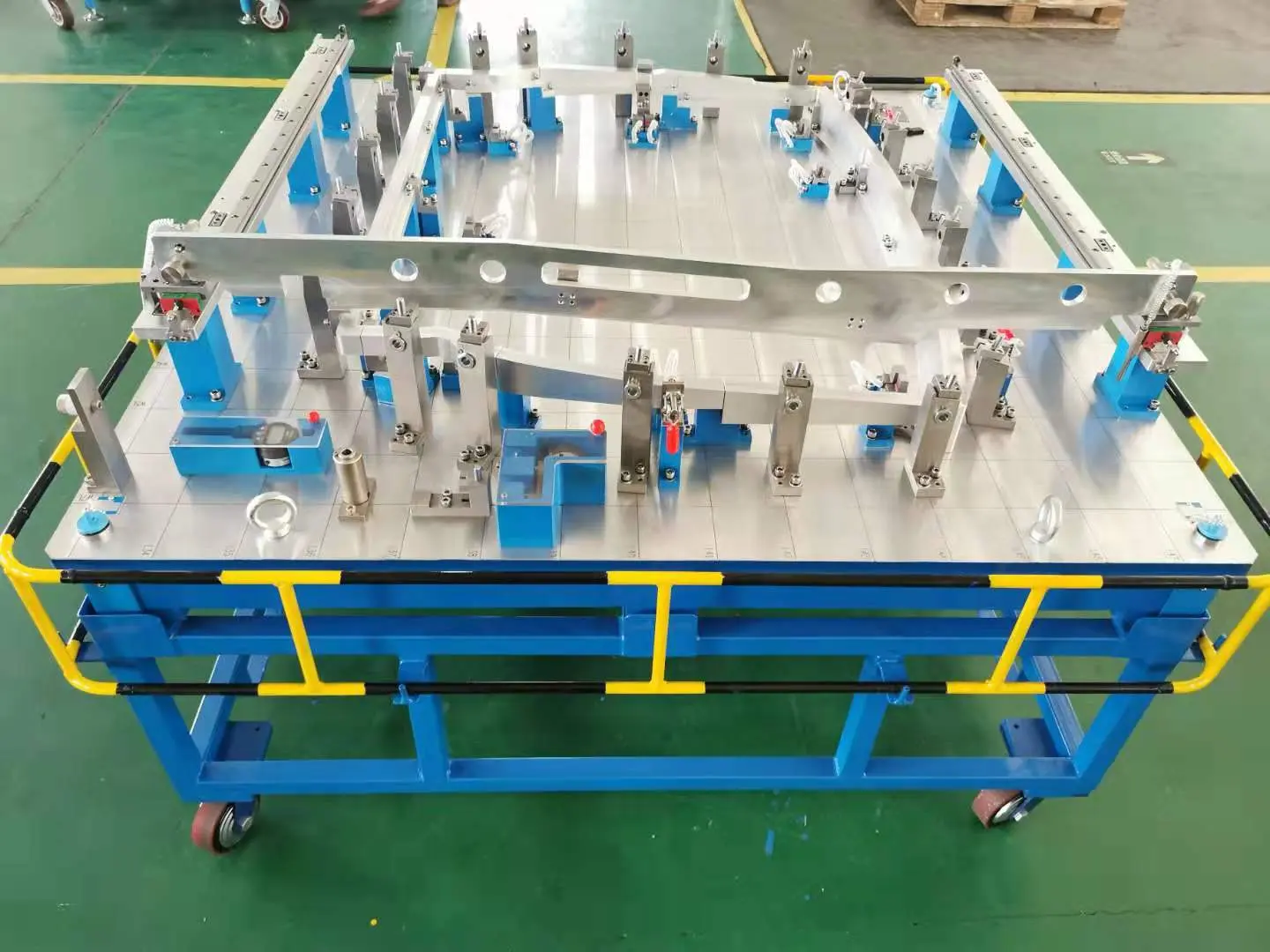

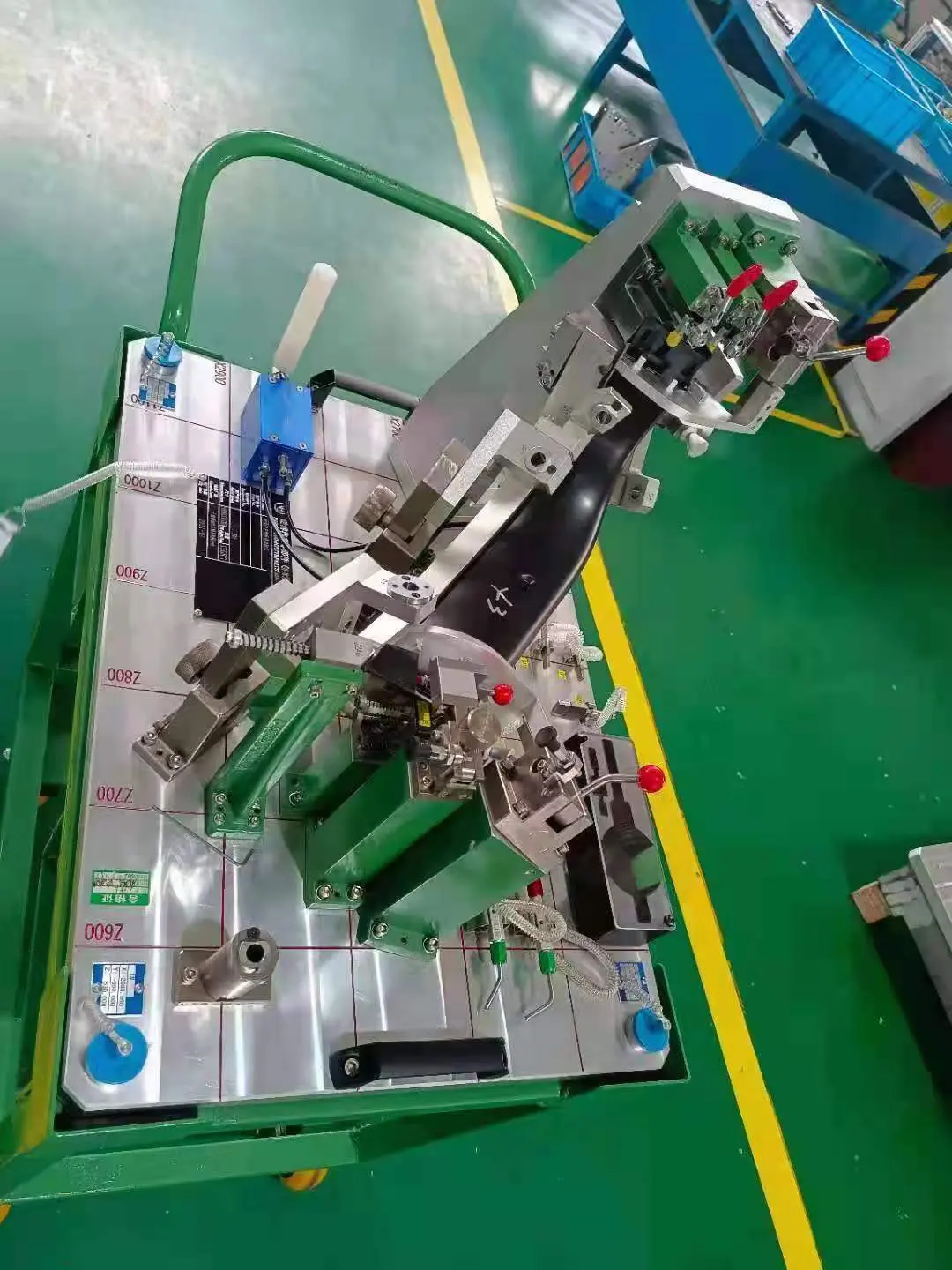

Checking fixtures are specialized tools used in the automotive industry to verify the dimensional accuracy and alignment of vehicle components during the manufacturing process. When it comes to the C-pillar, these fixtures are designed to precisely position and hold the various parts in place, allowing manufacturers to assess the fit and finish of the assembly. This is particularly important for the C-pillar, as any deviations in its alignment or dimensions can have a significant impact on the overall structural integrity and safety of the vehicle. By using checking fixtures specifically tailored for the C-pillar, manufacturers can ensure that this critical component meets the required specifications and standards.

Furthermore, checking fixtures for the C-pillar also play a vital role in streamlining the manufacturing process. By accurately positioning the components and providing a reference point for assembly, these fixtures help reduce the likelihood of errors and rework, ultimately saving time and resources. This is especially important in high-volume production environments, where efficiency and consistency are key to meeting production targets and delivering high-quality vehicles to customers. Additionally, the use of checking fixtures can also contribute to cost savings by minimizing scrap and rework, ultimately leading to improved overall profitability for automotive manufacturers.

In addition to ensuring dimensional accuracy and streamlining the manufacturing process, checking fixtures for the C-pillar also play a crucial role in quality control. By providing a standardized method for verifying the fit and alignment of the C-pillar components, these fixtures help identify any potential issues early in the production process, allowing for timely adjustments and corrections. This proactive approach to quality control not only helps prevent defects and non-conformities but also contributes to the overall safety and reliability of the vehicles being produced. As a result, checking fixtures for the C-pillar are an essential tool for automotive manufacturers looking to uphold the highest standards of quality and performance in their products.

In conclusion, the use of checking fixtures for the C-pillar is a critical aspect of automotive manufacturing, with far-reaching implications for quality, efficiency, and safety. These specialized tools not only ensure the dimensional accuracy and alignment of the C-pillar components but also contribute to streamlining the production process and maintaining high standards of quality control. As the automotive industry continues to evolve, the role of checking fixtures for the C-pillar will remain essential in driving the production of high-quality, reliable vehicles for consumers around the world.