Welding Fixture Tables are essential tools in the fabrication and manufacturing industry, providing a stable and precise platform for assembling and welding components. These tables play a crucial role in ensuring that metal parts are held securely in place during the welding process, which ultimately leads to greater accuracy and efficiency in the production line. By utilizing Welding Fixture Tables, fabricators can significantly reduce the risk of misalignment and improve the overall quality of their welds.

There are various types of Welding Fixture Tables, each designed to meet specific welding needs and applications. From modular systems that allow for customization to fixed tables optimized for particular projects, these fixtures enhance workflow and support a range of industries, including automotive, construction, and aerospace. Understanding the benefits and applications of Welding Fixture Tables not only empowers manufacturers to choose the right equipment but also helps them streamline their operations, leading to enhanced productivity and reduced operational costs.

A welding fixture table is a specialized piece of equipment designed to hold workpieces in the optimal position for welding. Unlike standard tables, these fixtures feature a combination of clamps, slots, and grids that allow for precise adjustment and stability during the welding process. This ensures that components are correctly aligned and securely held in place, which is crucial for achieving high-quality welds and maintaining dimensional accuracy.

The design of a welding fixture table can vary significantly based on its intended use, ranging from simple setups for small projects to complex configurations for large-scale manufacturing. These tables can adapt to different shapes and sizes of materials, accommodating a wide variety of welding techniques, including MIG, TIG, and stick welding. By providing a reliable platform, welding fixture tables enhance efficiency and safety in the workplace, reducing the likelihood of errors and improving overall productivity in welding operations.

Welding fixture tables play a crucial role in modern fabrication processes by providing a stable and precise platform for welding operations. One of the key benefits of using these tables is enhanced accuracy and repeatability. According to a report by the American Welding Society, the use of properly designed fixture tables can improve weld alignment precision by up to 50%. This level of accuracy is essential in industries where tolerances are tight, as even minor deviations can result in costly rework or structural failures.

In addition to precision, welding fixture tables significantly increase productivity. By allowing for the quick setup and repositioning of components, fabricators can reduce the time spent on each project. A study published in the Journal of Manufacturing Processes indicated that companies implementing advanced welding fixture technology reported a productivity increase of up to 30%. This boost not only accelerates project timelines but also enhances overall workflow efficiency, enabling teams to tackle larger volumes of work within tighter deadlines.

Moreover, welding fixture tables contribute to improved safety in the workplace. By securing components during the welding process, they minimize the risk of accidents caused by shifting materials. According to the Occupational Safety and Health Administration (OSHA), workplace injuries related to improper handling of materials can account for nearly 25% of all industrial accidents. The adoption of fixture tables effectively mitigates these risks, promoting a safer working environment for all personnel involved in welding operations.

| Dimension | Details |

|---|---|

| Material | Steel, Aluminum, Composite Materials |

| Weight Capacity | Up to 1000 kg |

| Surface Finish | Powder Coated, Galvanized |

| Adjustability | Manual and Automated Options |

| Common Applications | Automotive, Aerospace, Construction |

| Benefits | Increased Precision, Enhanced Workflow, Reduced Setup Time |

| Types | Modular, Fixed, Adjustable |

Welding fixture tables play a crucial role in the assembly and fabrication processes in various industries. They provide a stable and precise platform for the manipulation and joining of materials. Among the different types of welding fixture tables, the manual adjustable tables are highly valued for their flexibility and versatility. These tables allow operators to modify their setups according to specific project requirements, making them ideal for small to medium-scale production where customization is essential.

Another popular type is the pneumatic or hydraulic fixture table, designed for increased efficiency. These tables utilize pressurized air or hydraulic systems to assist in clamping and positioning workpieces quickly. This not only speeds up the welding process but also ensures consistent and accurate alignment of components, which is critical in high-volume manufacturing environments.

Additionally, modular fixture tables offer adaptability with interchangeable components, allowing users to create various workstations tailored to different tasks without the need for extensive reconfiguration.

Each type of welding fixture table brings unique benefits, catering to diverse applications from automotive to aerospace manufacturing. By understanding the distinct features of these tables, professionals can select the most suitable option for their particular welding needs, enhancing productivity and ensuring high-quality welds.

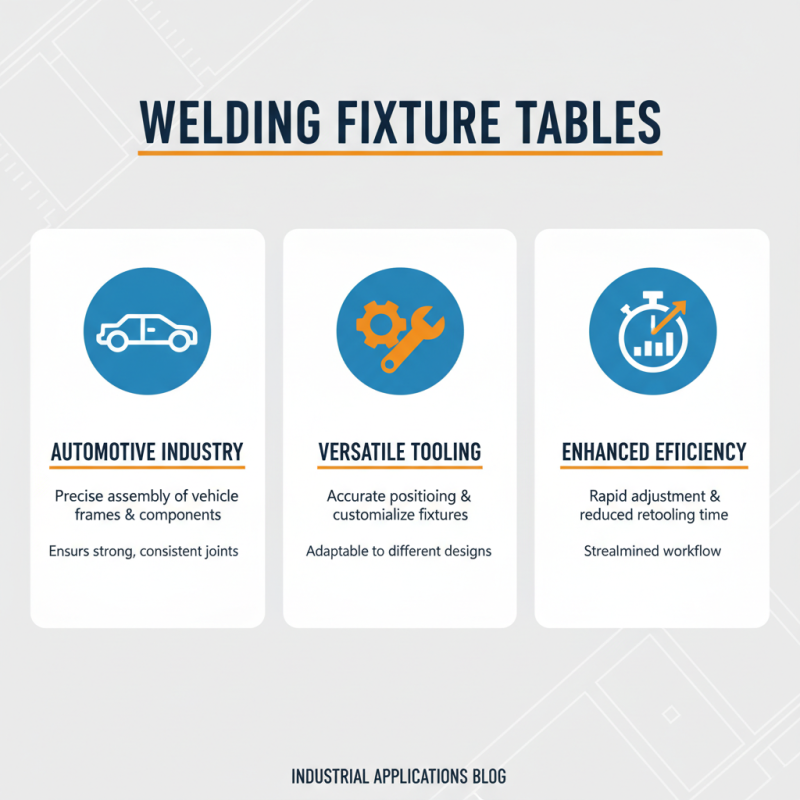

Welding fixture tables are versatile tools that play a crucial role in a variety of industrial applications. One of the most common uses is in the automotive industry, where precise welds are essential for assembling vehicle frames and components. These tables allow for the accurate positioning of parts, ensuring that the welding process produces strong, consistent joints. The ability to adjust and customize fixtures on the table enhances workflow efficiency, as operators can quickly adapt to different vehicle designs without extensive retooling.

In addition to automotive manufacturing, welding fixture tables are widely used in the aerospace sector. Here, the need for precision is paramount due to the stringent safety regulations and complex components involved. Utilizing fixture tables allows for the assembly of intricate structures, such as fuselages and wing assemblies, with a high degree of accuracy. Furthermore, these tables facilitate the testing and inspection of welded joints, ensuring that every piece meets high-quality standards before reaching the final assembly line. This level of control not only improves product quality but also enhances overall operational productivity.

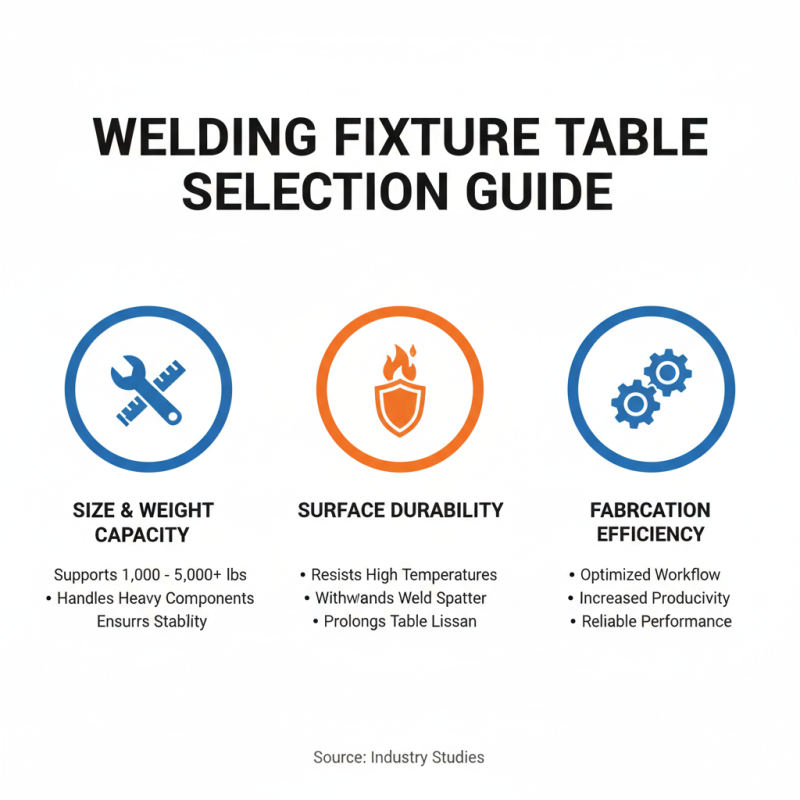

When selecting a welding fixture table, several key factors come into play that can significantly influence fabrication efficiency and overall productivity. First and foremost, the size and weight capacity of the table are crucial. According to industry studies, a sturdy welding fixture table should support weights ranging from 1,000 to over 5,000 pounds, depending on the materials and projects involved. This capacity ensures the table can handle heavy components without compromising stability. Additionally, the working surface must be designed to withstand high temperatures and potential spatter from welding processes, which leads to prolonged durability.

Another important consideration is adjustability and flexibility. Welding operations often require varied setups; thus, tables that offer features such as modular configurations or height adjustability can enhance workflow. A report from the American Welding Society indicates that flexible workstations can reduce fabrication time by up to 30%, making them a valuable investment in increasing operational efficiency. Finally, the tabletop's material plays a pivotal role. Steel tables, for instance, provide excellent durability and heat resistance, while aluminum tables are lighter and more portable. Ultimately, evaluating these critical factors will help in selecting a welding fixture table that maximally supports the specific applications and demands of the welding operation.