In the realm of manufacturing, maintaining product quality is paramount, and Inspection Fixtures play a crucial role in this process. These specialized tools are designed to hold and support parts during inspections, ensuring accuracy and consistency in measurements. According to a report from McKinsey, over 70% of manufacturing defects can be traced back to inadequate quality control processes. Furthermore, a study by the National Institute of Standards and Technology (NIST) indicates that effective quality control can reduce production costs by as much as 30%. By utilizing Inspection Fixtures, manufacturers can detect defects early in the production cycle, thus minimizing waste and enhancing overall efficiency. Ultimately, the integration of these fixtures into manufacturing workflows not only boosts quality assurance but also contributes to improved operational performance and customer satisfaction.

In the realm of manufacturing, maintaining product quality is paramount, and Inspection Fixtures play a crucial role in this process. These specialized tools are designed to hold and support parts during inspections, ensuring accuracy and consistency in measurements. According to a report from McKinsey, over 70% of manufacturing defects can be traced back to inadequate quality control processes. Furthermore, a study by the National Institute of Standards and Technology (NIST) indicates that effective quality control can reduce production costs by as much as 30%. By utilizing Inspection Fixtures, manufacturers can detect defects early in the production cycle, thus minimizing waste and enhancing overall efficiency. Ultimately, the integration of these fixtures into manufacturing workflows not only boosts quality assurance but also contributes to improved operational performance and customer satisfaction.

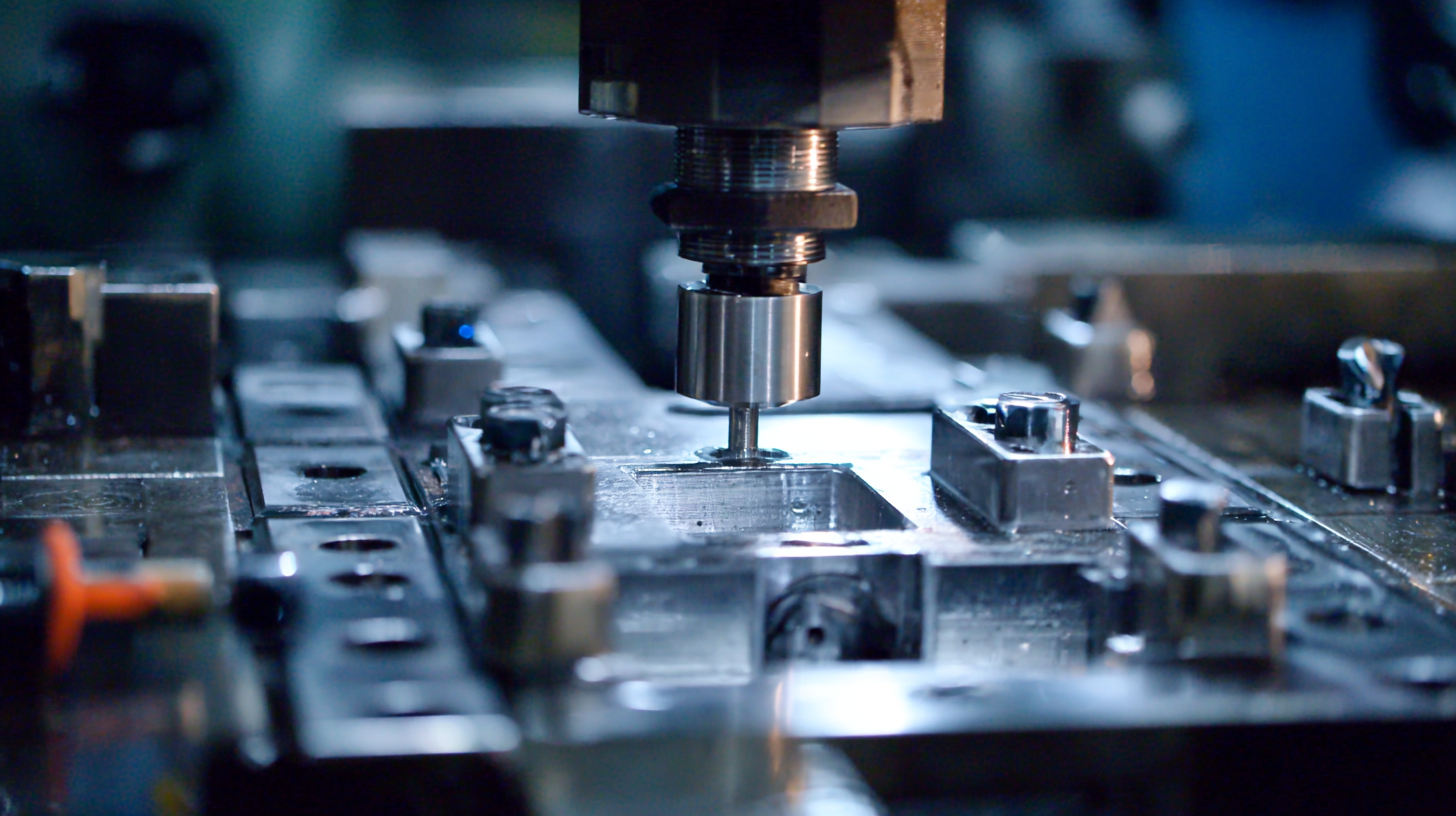

Inspection fixtures play a critical role in ensuring dimensional accuracy within manufacturing processes. By leveraging advanced measurement technologies, manufacturers can significantly reduce the risk of defects and enhance product quality. Recent developments, including the deployment of horizontal-arm coordinate measuring machines for inspecting next-generation automotive fixtures, highlight the industry's focus on precision. These machines are designed to provide high accuracy in measuring part dimensions, crucial for meeting stringent quality standards in automotive production.

Moreover, innovations such as computed tomography (CT) scanning are revolutionizing quality assurance, especially in the medical device sector. Described as one of the most advanced measurement technologies available, CT scanning allows for non-destructive testing of complex geometries, providing detailed insights into the internal structure of products. According to industry reports, organizations that integrate advanced inspection technologies have reported a decrease in production errors by up to 30%, showcasing the tangible benefits of employing robust inspection fixtures. The integration of these technologies not only ensures dimensional accuracy but also sets a foundation for continuous improvement in manufacturing practices.

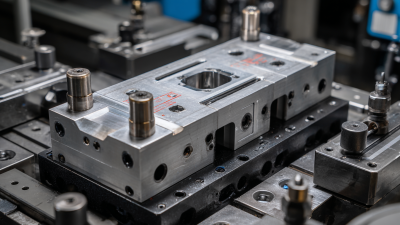

Effective inspection fixtures are critical tools in quality control, as they ensure that products meet specific design and manufacturing standards. One of the key design features of these fixtures is the ability to securely hold the item being inspected in a precise orientation. This aligns the product perfectly for measurement and examination, eliminating the possibility of human error. The materials used for these fixtures should be durable and stable, allowing for repeated use without degradation of performance.

When designing an inspection fixture, consider incorporating adjustable features that can accommodate different product sizes and shapes. This flexibility not only maximizes the utility of the fixture but also enhances inspection accuracy across various batches of products. Additionally, integrating easy-to-read measurement indicators can streamline the inspection process, allowing operators to quickly identify discrepancies.

**Tips:** When creating inspection fixtures, prioritize ergonomics to minimize operator fatigue. This can lead to improved efficiency during the quality control process. Also, involve team members from both design and production in the fixture development to ensure practical functionality and to address potential issues early. Lastly, regular testing and refinement of the inspection fixtures can further enhance their effectiveness in maintaining product quality.

| Feature | Description | Benefits |

|---|---|---|

| Material Selection | Choosing durable materials that withstand wear and maintain precision. | Increases longevity and reduces the need for frequent replacements. |

| Adjustability | Fixtures that can be easily adjusted to accommodate different part sizes. | Enhances versatility in inspection processes. |

| Alignment Features | Integrated systems to ensure proper alignment of parts during inspection. | Improves accuracy and repeatability in measurements. |

| Ergonomic Design | Designs that minimize strain and enhance user comfort during operation. | Increases efficiency and reduces operator fatigue. |

| Integration with Measurement Tools | Features compatible with various inspection and measurement devices. | Streamlines the inspection process and enhances data collection. |

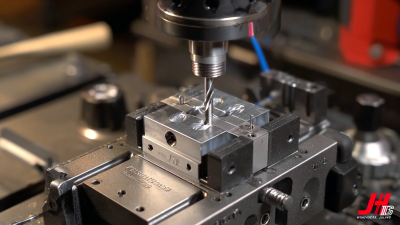

Implementing inspection fixtures in manufacturing processes is essential for enhancing product quality and ensuring consistency. These tools are designed to hold and support parts during inspection, allowing for precise measurements and evaluations. To effectively implement inspection fixtures, manufacturers should focus on designing fixtures that are tailored to specific parts and processes. This customization ensures that the fixtures provide the necessary stability and accuracy, reducing variability in measurements.

Tips: When creating inspection fixtures, consider incorporating adjustable elements to accommodate different part dimensions. This flexibility can significantly extend the lifespan of your fixtures and reduce the need for frequent replacements.

Additionally, training operators on the proper use of these fixtures can greatly improve inspection outcomes. Providing detailed guidelines and hands-on training sessions helps ensure that team members are well-equipped to utilize the fixtures efficiently.

Tips: Regularly review and refine the training programs based on feedback and observed efficiencies, which can lead to better performance and fewer errors in the inspection process.

Inspection fixtures play a crucial role in maintaining quality control within manufacturing processes, yet their implementation is not without challenges. One common issue is the initial cost of setting up these fixtures, which can amount to significant investments, often cited as ranging from $5,000 to $100,000 depending on complexity and customization (Statista, 2021). Many companies may hesitate to invest in these tools, fearing that the return on investment will not justify the expenditure. However, the long-term benefits, such as enhanced product quality and reduced defects—the latter of which can lead to savings of up to 30% in production costs (Quality Digest, 2022)—often outweigh initial financial concerns.

Another significant challenge lies in ensuring that inspection fixtures are adaptable and maintainable. Changes in product design or manufacturing processes can render existing fixtures obsolete, which could lead to increased downtime and additional costs. A report from the American Society for Quality points out that up to 70% of manufacturing efficiency can be lost due to outdated inspection methods. To combat this, manufacturers should implement modular design principles and conduct regular reviews of their quality control processes. By investing in versatile inspection systems and ongoing training for staff, companies can mitigate these challenges, ensuring that their inspection fixtures continue to enhance quality control effectively.

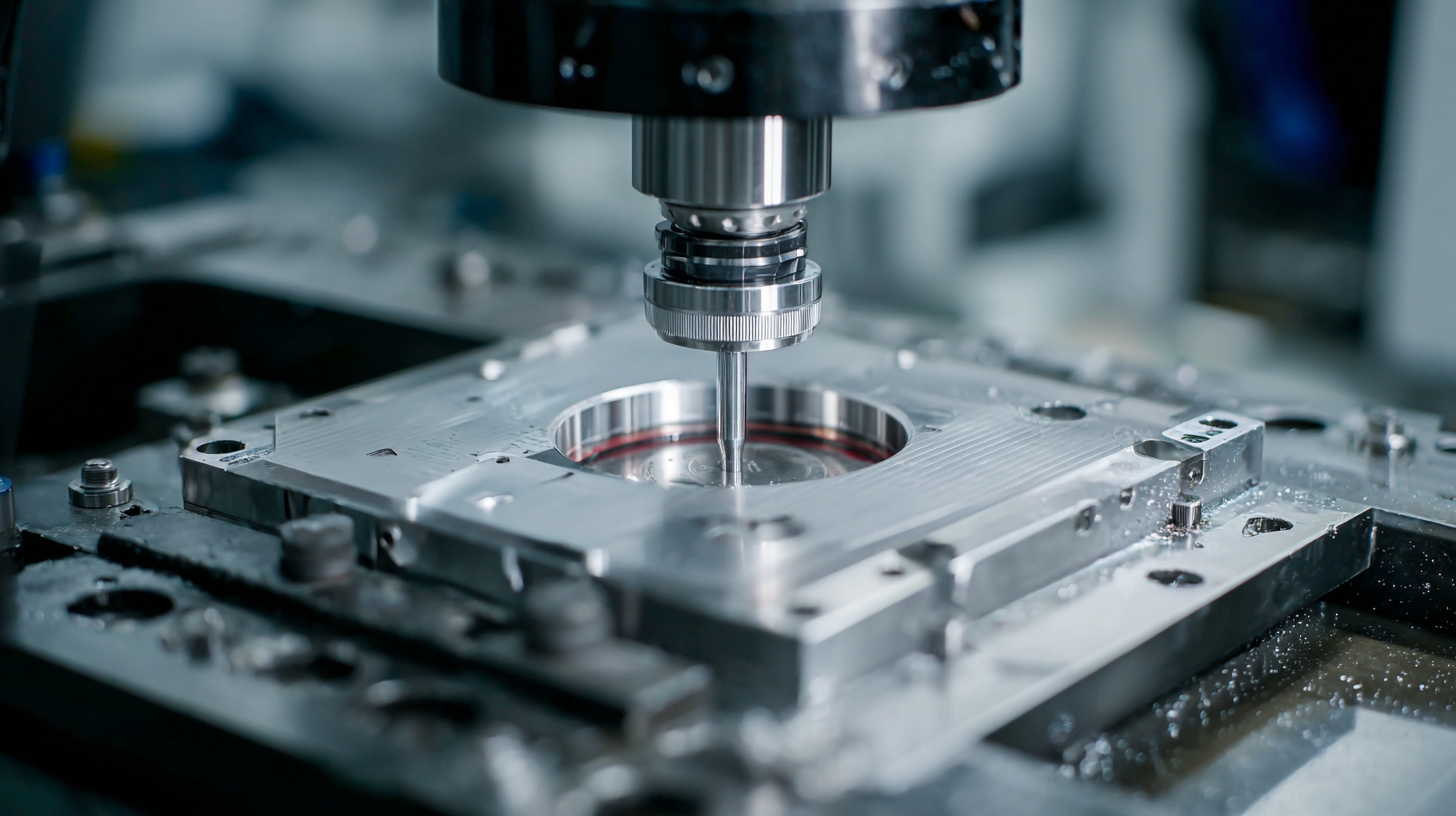

Inspection fixtures are a fundamental component in ensuring quality control within manufacturing processes. By providing a stable and repeatable platform for inspecting parts, these fixtures play a critical role in maintaining production quality. When parts are secured in a consistent orientation during measurement, the likelihood of human error diminishes significantly. According to industry reports, implementing proper fixturing can lead to a reduction in defect rates by as much as 30%, which underscores its importance in maintaining high standards of production.

The return on investment (ROI) associated with inspection fixtures is noteworthy. While the initial costs may appear significant, the long-term savings achieved through reduced rework and scrap often outweigh these expenses. Case studies reveal that manufacturers who adopted advanced fixturing techniques experienced an average increase in productivity by 25%, paired with enhanced accuracy in measurements. Such improvements not only boost operational efficiency but also contribute to overall customer satisfaction, thus establishing a stronger market presence. By evaluating the ROI of inspection fixtures, organizations can make informed decisions that align quality control with their strategic business goals.

This chart demonstrates the ROI of implementing different types of inspection fixtures in manufacturing processes. As the use of these fixtures increases, the quality of production significantly improves, leading to fewer defects and higher customer satisfaction.