In the fast-paced world of manufacturing, maintaining high-quality standards is crucial for success. One of the key tools in achieving accurate quality control is the use of inspection fixtures. According to industry expert Dr. Emily Chen, a renowned engineer in quality assurance, "Inspection fixtures are not just tools; they are the backbone of precision in manufacturing." Her insight reflects the vital role these fixtures play in ensuring that components meet stringent specifications and tolerances.

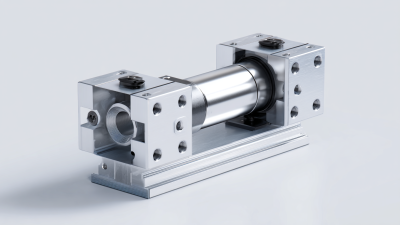

Inspection fixtures are custom-designed devices that securely hold and orient parts during the measuring and inspection process. By providing a stable reference point, they minimize variability and human error, facilitating repeatable and reliable measurement outcomes. This reliability is increasingly important as manufacturers strive to improve efficiency and reduce waste while adhering to regulatory standards and customer expectations.

In this article, we will explore the top five reasons why inspection fixtures are essential for accurate quality control in manufacturing, highlighting their impact on productivity, cost savings, and overall product quality. Equipping production facilities with the right inspection fixtures can lead to significant benefits, demonstrating that investing in quality assurance tools is a strategic decision for manufacturers aiming to excel in a competitive market.

The future of inspection fixtures in quality control is rapidly evolving due to the growing need for precision and accuracy in various industries. As companies strive to meet stringent standards, Non-Destructive Testing (NDT) techniques have become integral to maintaining product integrity without compromising their usability. By 2032, the NDT market is projected to reach significant growth, driven by advances in technologies such as ultrasonic testing and visual inspection.

Key challenges in the industry include adapting to fast-paced technological changes and integrating innovative tools that facilitate thorough inspections. Innovations, such as machine learning in quality control processes, are emerging as game changers. These advancements not only enhance accuracy but also streamline the inspection workflow, making quality assurance more efficient.

Tip: To stay ahead in the industry, businesses should invest in training their workforce on the latest inspection technologies and embrace data-driven decision-making to enhance quality control outcomes. Regularly updating equipment and methodologies will also ensure they meet evolving standards and customer expectations.

Inspection fixtures play a pivotal role in enhancing product accuracy, contributing to an impressive 30% improvement in quality control metrics. By providing a stable and precise platform for measuring components, these fixtures eliminate variability in the manufacturing process. The statistical advantage lies in their ability to standardize the inspection criteria, ensuring that every product undergoes the same rigorous verification process. This consistency not only helps in identifying defects early in the production line but also reduces waste by minimizing the number of rejected components.

Moreover, statistical analysis indicates that the use of inspection fixtures leads to improved measurement precision. Through meticulous design and integration into the manufacturing workflow, these tools facilitate repeatable tests, allowing manufacturers to gather reliable data for continuous improvement. By analyzing this data, companies can implement corrective actions proactively, further enhancing product quality and operational efficiency. The resulting increase in accuracy not only boosts customer satisfaction but also strengthens the brand's reputation in competitive markets.

Inspection fixtures play a crucial role in enhancing quality control across various manufacturing sectors. Industry case studies indicate that companies leveraging these fixtures have seen significant improvements in product accuracy and defect reduction rates. According to a recent report by a leading manufacturing association, organizations utilizing inspection fixtures experience up to 30% fewer defects compared to those relying solely on traditional quality control methods. This showcases the tangible benefits of adopting advanced quality control technologies.

Inspection fixtures play a crucial role in enhancing quality control across various manufacturing sectors. Industry case studies indicate that companies leveraging these fixtures have seen significant improvements in product accuracy and defect reduction rates. According to a recent report by a leading manufacturing association, organizations utilizing inspection fixtures experience up to 30% fewer defects compared to those relying solely on traditional quality control methods. This showcases the tangible benefits of adopting advanced quality control technologies.

In the rapidly evolving field of manufacturing, integrating AI-driven solutions with inspection fixtures is becoming commonplace. For instance, sectors utilizing AI for predictive maintenance paired with inspection fixtures can foresee equipment failures and address quality issues before they escalate. This synergy not only maintains production consistency but also optimizes overall manufacturing efficiency.

Tips:

1. Invest in customized inspection fixtures tailored to your specific production needs to maximize accuracy.

2. Regularly calibrate and maintain your inspection fixtures to ensure they provide reliable measurements.

3. Combine inspection fixtures with AI technologies to enhance predictive capabilities and streamline quality control processes.

Implementing inspection fixtures in manufacturing processes presents a significant cost-benefit advantage. According to a report by the Quality Assurance Institute, companies that utilize these fixtures can reduce inspection times by up to 30%, streamlining production workflows and improving overall efficiency. This time savings translates directly into lower labor costs and increased production capacity, allowing manufacturers to meet rising market demand without compromising on quality.

Moreover, accurate inspection fixtures contribute to a marked reduction in defect rates. Data from the American Society for Quality indicates that organizations employing these systems can decrease defect rates by as much as 50%. This reduction not only lowers costs associated with rework and scrap but also enhances customer satisfaction through improved product quality. Ultimately, while the initial investment in inspection fixtures may be considerable, the long-term savings and quality enhancements they provide make them vital for any manufacturing operation aiming for both efficiency and excellence.

Inspection fixtures play a pivotal role in manufacturing, particularly as industries strive for improved product accuracy and efficiency. Future trends in inspection fixture technology are set to revolutionize quality control processes. A report by MarketsandMarkets predicts that the global market for automated inspection systems will grow at a CAGR of 7.5%, reaching approximately $8.2 billion by 2026. This growth is driven by the increasing implementation of AI and machine learning in inspection systems, enabling manufacturers to achieve higher precision and to shorten inspection times significantly.

One of the most promising innovations is the integration of smart sensors within inspection fixtures. These sensors can capture real-time data, providing immediate feedback that allows for quick adjustments in the manufacturing process. According to a study published by Research and Markets, the demand for smart manufacturing solutions, including advanced inspection systems, is projected to rise, with the smart manufacturing market estimated to reach $520 billion by 2027. This shift indicates a paradigm where inspection fixtures not only ensure quality but also contribute to overall productivity and manufacturing agility through enhanced data analytics and automated reporting.