In recent years, the global manufacturing landscape has witnessed a significant shift, with buyers increasingly recognizing the upgraded quality of Chinese-made part fixtures. According to the 2022 Global Manufacturing Report, China's production capabilities have expanded, with a remarkable 40% increase in the export of precision tooling and fixtures since 2019. This evolution is primarily attributed to advancements in technology, rigorous quality standards, and a commitment to innovation among Chinese manufacturers. As a result, industries ranging from automotive to aerospace are turning to Chinese suppliers for high-performance part fixtures that not only meet but often exceed international quality benchmarks. With the global market for manufacturing fixtures projected to reach $10 billion by 2025, it is essential for stakeholders to understand the advantages of sourcing from China, as these fixtures are poised to enhance operational efficiency and drive competitive advantage.

As global buyers increasingly turn their attention to Chinese manufacturing, a noticeable trend is the commitment to quality improvement among manufacturers. This shift is not merely a marketing strategy but a response to the demands of international standards and consumer expectations. Enhanced quality control processes, investment in advanced technologies, and skilled labor training have become pivotal in the production of best part fixtures. The result is a range of products that not only meets but often exceeds global benchmarks.

Tip: When sourcing from China, it's essential to conduct thorough research on the manufacturer's quality certifications and production capabilities. Look for manufacturers who have adopted international standards such as ISO, as these can be indicators of their commitment to quality improvement.

Moreover, collaborations with foreign partners have led to knowledge exchange and innovation within the Chinese manufacturing landscape. This synergy drives the development of superior materials and design capabilities, resulting in fixtures that are not only durable but also highly functional.

Tip: Always request samples before making large orders. This practice allows buyers to assess the quality firsthand and ensures that the products will meet their specifications and performance expectations.

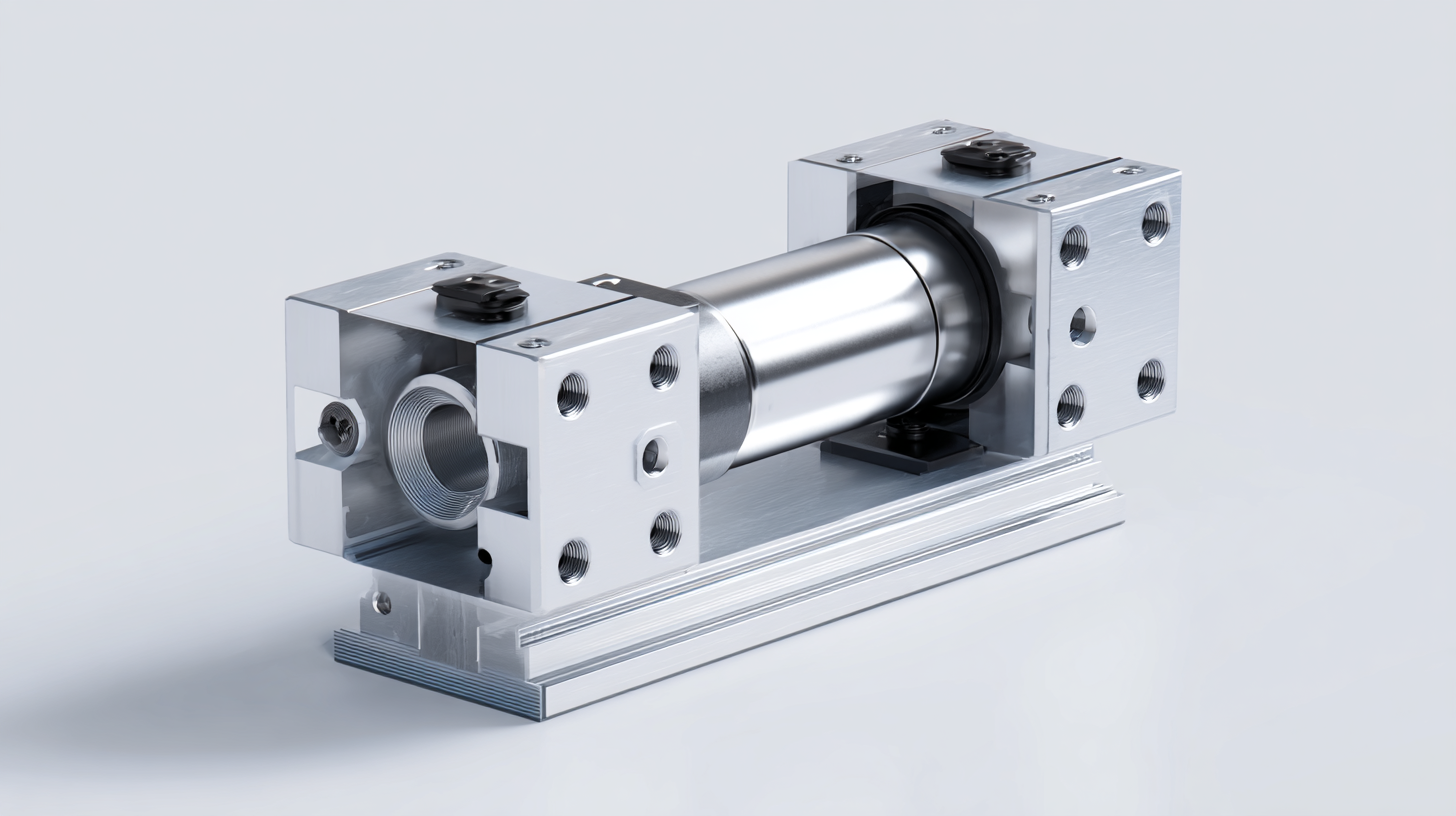

The intersection of technological advancements and manufacturing prowess has led to a noticeable evolution in the production of part fixtures in China. New technologies, such as automation and advanced materials, have significantly improved the precision and durability of these components. Modern factories are now armed with state-of-the-art machinery that allows for rapid prototyping and customization, ensuring that the fixtures not only meet but often exceed the global standards expected by buyers.

Moreover, the integration of artificial intelligence and data analytics into the manufacturing process has optimized workflows and minimized waste. This enhances overall efficiency, enabling manufacturers to produce high-quality fixtures at competitive prices. Global buyers have taken notice of these improvements, appreciating the enhanced quality and reliability that Chinese-made products now offer. As these technological advancements continue to reshape the industry, the perception of Chinese manufacturing is shifting towards one of innovation and excellence in quality.

The chart below illustrates the improvement in quality metrics of Chinese-made part fixtures over the past five years, highlighting the influence of technological advancements in production methods.

Global buyers are increasingly recognizing the advantages of sourcing high-quality part fixtures from Chinese manufacturers. Recent case studies highlight the successes of businesses that have made the leap to integrate Chinese factories into their supply chain. According to a report by Mordor Intelligence, the global manufacturing market is expected to grow at a CAGR of 3.6% from 2021 to 2026, with China remaining a key player due to its innovation and production capabilities. Companies that partner with Chinese factories can often achieve cost reductions of up to 30% while maintaining quality standards that compete with Western counterparts.

When considering sourcing from China, it’s essential to evaluate potential partners thoroughly. Look for manufacturers with ISO certifications, as they indicate adherence to international quality standards. Additionally, businesses should establish clear communication channels to ensure that specifications and expectations are understood from the outset. Leveraging technology, such as virtual inspections and real-time updates, can also enhance the sourcing process and ensure that buyers are kept informed throughout production.

One major tip for global buyers is to visit factories when possible to build relationships and ensure that the production environment meets your standards. Engaging directly with decision-makers can facilitate smoother negotiations and foster trust. Additionally, consider incorporating a trial order to assess quality and delivery timelines before committing to larger quantities. This careful approach minimizes risks and leads to more sustainable sourcing decisions.

| Country | Industry | Product Type | Quality Improvement (%) | Cost Reduction (%) | Lead Time (Days) |

|---|---|---|---|---|---|

| USA | Automotive | Engine Parts | 15 | 20 | 30 |

| Germany | Electronics | Circuit Boards | 25 | 15 | 25 |

| Japan | Aerospace | Components | 20 | 10 | 40 |

| Canada | Construction | Fixtures | 18 | 22 | 35 |

In recent years, global perceptions of Chinese manufacturing quality have undergone a significant transformation. Once regarded primarily for cost-effectiveness, many international buyers are now recognizing the high standards of production that Chinese manufacturers offer. According to a report from the China Institute of Manufacturing, over 70% of global companies expressed satisfaction with the quality of Chinese-made products in 2023, a notable increase from previous years. This growing trust in Chinese manufacturing is attributed to enhanced production techniques and stricter quality controls, aligning with international standards.

When sourcing high-quality fixtures, buyers should consider a few essential tips. First, evaluate certifications and compliance with international quality standards, such as ISO 9001. This ensures that the manufacturer adheres to rigorous quality management principles. Secondly, always request product samples or prototypes before placing large orders; this allows you to assess the quality firsthand. Lastly, building relationships with manufacturers can lead to better communication and customized solutions tailored to specific needs.

When sourcing high-quality fixtures, buyers should consider a few essential tips. First, evaluate certifications and compliance with international quality standards, such as ISO 9001. This ensures that the manufacturer adheres to rigorous quality management principles. Secondly, always request product samples or prototypes before placing large orders; this allows you to assess the quality firsthand. Lastly, building relationships with manufacturers can lead to better communication and customized solutions tailored to specific needs.

The shift in mindset highlights that Chinese manufacturers are not just competing on price but are also elevating their status in the global marketplace through quality enhancements. With ongoing investments in technology and workforce training, the future for Chinese-made products looks increasingly promising.

As global buyers increasingly recognize the enhanced quality of Chinese manufactured fixtures, the sustainability practices within China's manufacturing sector have also entered the spotlight. In recent years, Chinese manufacturers have adopted innovative techniques and sustainable materials, aiming to reduce their environmental footprint while maintaining high production standards. This shift is not only a response to international demand for greener products but also a commitment to creating a more sustainable future.

One significant aspect of this transformation is the integration of circular economy principles. Manufacturers are focusing on minimizing waste by reusing materials and optimizing production processes. Additionally, many companies are investing in renewable energy sources and implementing eco-friendly technologies. This proactive approach not only elevates the quality of products but also aligns with the global trend towards sustainability. By embracing these practices, Chinese manufacturers are setting a new standard, positioning themselves as leaders in the high-quality, environmentally conscious market.