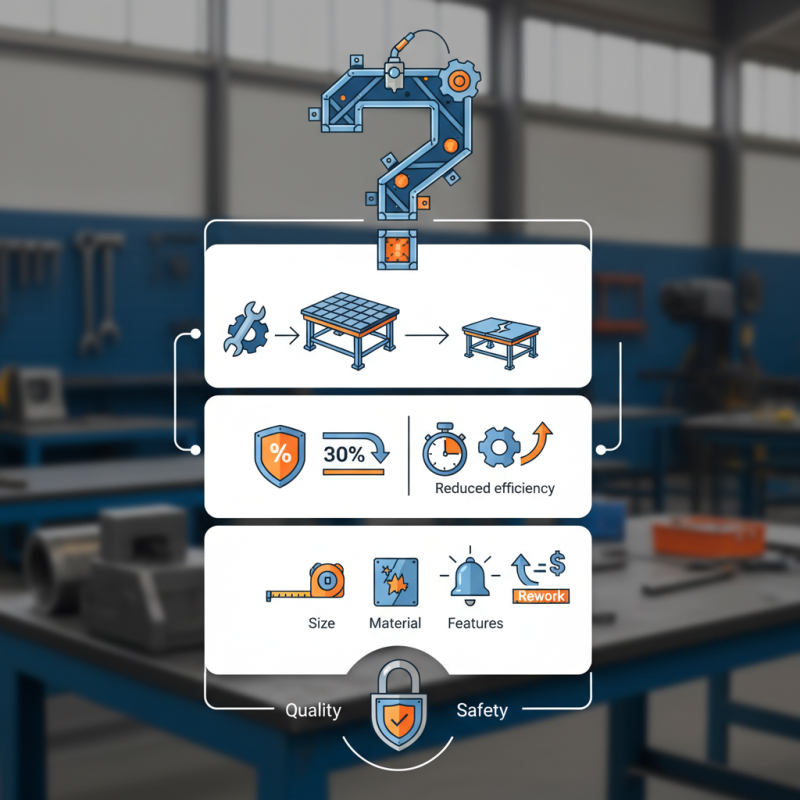

Choosing the right welding fixture tables is crucial for project efficiency and quality. According to the American Welding Society, improper fixtures can lead to a 30% increase in rework costs. This highlights the importance of selecting the appropriate welding fixture tables that meet specific project needs.

Welding fixture tables vary in size, material, and features. Some offer adjustable heights; others provide grid systems for accurate alignment. Each feature influences productivity and precision. A well-chosen fixture table can significantly boost output and reduce errors. Yet, many overlook these details, leading to inefficiencies.

Knowledge of project demands is vital. Custom-built options may solve unique challenges, yet they require thoughtful consideration. A one-size-fits-all solution often falls short. Understanding your workload and potential hazards is essential. Investing in the right welding fixture tables is an investment in quality and safety in the long run.

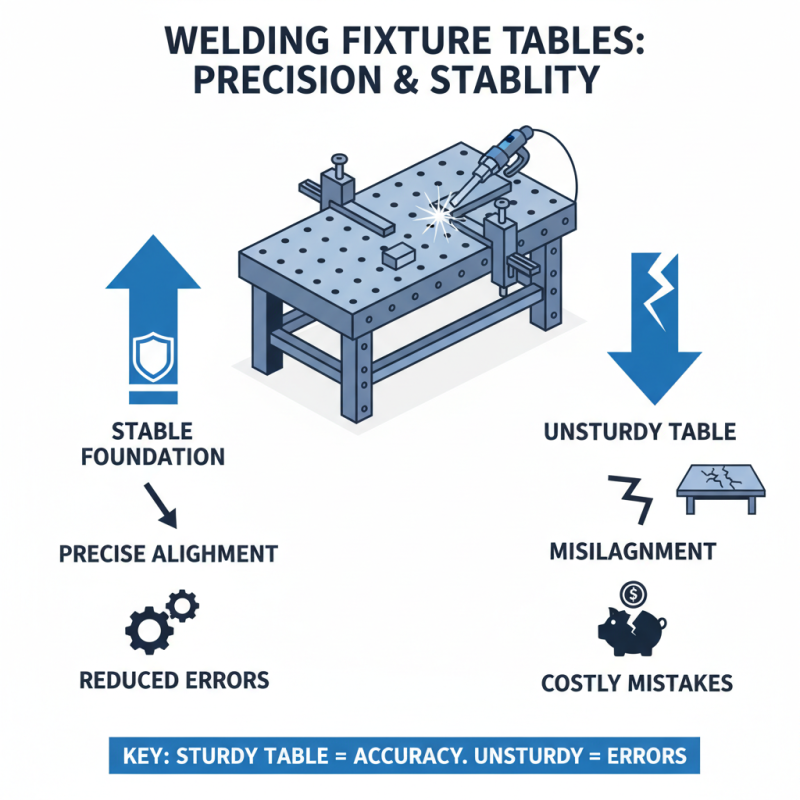

Welding fixture tables are critical in any welding project. They provide a stable foundation for precise alignment and secure placement of materials. Using these tables effectively can greatly reduce errors. If the table isn't sturdy, it may lead to misalignment. Misalignment can cause costly mistakes.

The importance of choosing the right fixture table cannot be overstated. A poorly chosen table can lead to frustration. Adjusting your setup repeatedly wastes time. You might find that a table doesn’t accommodate larger pieces, causing delays. Understanding the dimensions you need is vital. The right table should fit your specific needs.

Additionally, consider surface material and finish. Some surfaces are better for certain types of welding. A smooth table may be ideal for certain projects, while a rough bed could offer better grip for others. Reflecting on your past projects can guide your choice. What worked? What didn’t? It’s about finding the right fit for your unique requirements.

When selecting welding fixture tables, several key factors deserve attention. Firstly, consider the table's size and load capacity. The right dimensions help accommodate large projects without compromising stability. A sturdy table can support heavy materials, ensuring safe and effective welding. If the table is too small, it becomes difficult to work efficiently. This oversight can lead to inaccuracies in your welds.

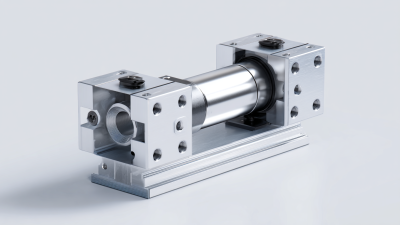

Another essential factor is the adjustability of the fixture table. Tables that offer customization allow you to make quick adjustments during the welding process. Fixed tables may limit flexibility, forcing you to compromise on project requirements. Think about your typical projects: how often do you need to change setups? It’s crucial to find a balance between versatility and strength.

Finally, the material of the table impacts its durability and heat resistance. Steel tables are popular, but they can rust over time. Some may need coatings or regular maintenance to prevent degradation. It's worth considering how often you're willing to maintain your equipment. These details matter and can affect your long-term productivity. Reflect on these factors to choose wisely.

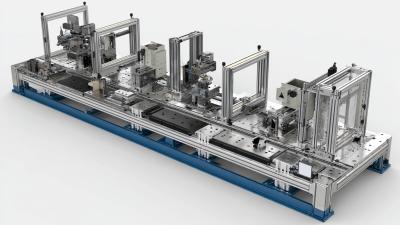

When selecting welding fixture tables, consider the various types available. Each type serves specific applications in welding projects. For instance, fixed tables offer stability for repetitive tasks. They are ideal for projects requiring precision. On the other hand, adjustable tables are versatile. You can modify their height or angle for different welding positions.

Tips: Always evaluate your project needs first. Think about space and mobility. Portable welding tables are useful for on-site jobs.

Rotating tables enhance efficiency. They allow welders to reach different angles with ease. This reduces the need for repositioning parts. However, they might not be suitable for heavy-duty work. Consider weight limits when making your choice.

To summarize, understanding these types helps in making informed decisions. Assessing your specific requirements can prevent mistakes later. Do not rush into a purchase; think it through.

| Type of Welding Fixture Table | Material | Load Capacity (lbs) | Best Suited For | Typical Applications |

|---|---|---|---|---|

| Fixed Welding Fixture Table | Steel | 1000 | Heavy Duty Welding | Structural Components |

| Adjustable Welding Fixture Table | Aluminum | 750 | Versatile Welding | Custom Fabrication |

| Portable Welding Fixture Table | Composite Materials | 500 | Field Applications | On-site Repairs |

| Rotary Welding Fixture Table | Cast Iron | 1200 | Automated Welding | High-Precision Parts |

| T-slot Welding Fixture Table | Mild Steel | 600 | Flexible Welding | Prototype Development |

When choosing a welding fixture table, material selection plays a crucial role in durability and effectiveness. Common materials include steel, aluminum, and composite metals.

Steel is heavy and strong, making it ideal for heavy-duty projects. It can withstand high temperatures and stress. According to industry reports, approximately 70% of welding tables are constructed from steel for this reason. However, steel can rust if not properly treated.

Aluminum offers a lightweight alternative. It is easier to maneuver, which can speed up project timelines. However, aluminum may not handle as much weight as steel. A study indicates that approximately 25% of professionals prefer aluminum for lighter applications. Composite materials, though less common, provide corrosion resistance and flexibility. These could be beneficial for specialized tasks but often come with a higher cost and require careful handling.

Tips: When selecting a material, consider the weight of the items you'll be welding. Too heavy for a flimsy table? You might face issues. Also, assess your working environment. Is there moisture? Steel might need extra care to prevent rust.

Ultimately, consider your specific needs. Reflect on the types of projects you’ll tackle. Are you crafting intricate designs or heavy structures? Your choice can influence precision and safety. Choose wisely may prevent future headaches.

When considering welding fixture tables, budgeting is critical. Low-cost options may seem appealing, but they often lack durability and precision. According to a recent industry report, investing in higher-quality tables can increase productivity by up to 30%. Cheaper tables may lead to frequent replacements or repairs, which can inflate long-term costs.

Analyzing initial costs versus potential savings is essential. A mid-range welding table, priced around $2,500, can provide robust support and versatility. In contrast, a lower-end table might cost $1,200 but may not meet project demands. This gap can result in more wastage and rework. Furthermore, the industry average shows that about 15-20% of project budgets are wasted on poor-quality tools.

Take the time to assess what features are necessary. A table with modular design can adapt to different projects, adding value. However, not every project needs a high-end table. Sometimes, basic functions suffice. Each workshop's needs vary, and reevaluating them periodically can prevent overspending. Balancing functionality, quality, and price is crucial for successful outcomes.