When it comes to setting up an efficient and productive workshop, choosing the right tools is essential, and Welding Fixture Tables stand out as a critical component in this process. These tables not only offer a solid workspace for various welding projects but also enhance the accuracy and stability of your workpieces. With a myriad of options available, selecting the best Welding Fixture Tables tailored to your specific needs can be challenging. Factors such as size, material, design, and versatility should all be taken into consideration to ensure that your investment suits both current and future projects. In this guide, we will explore the key aspects to look for in Welding Fixture Tables, helping you make an informed decision that will streamline your workflow and elevate the quality of your welding tasks.

When selecting welding fixture tables for your workshop, several critical factors must be taken into account to ensure optimal performance and efficiency. According to the American Welding Society, the right fixture table can increase productivity by up to 30%, making it a worthwhile investment. First, consider the material of the table; heavy-duty steel tables offer durability and stability, essential for precise welding tasks. Additionally, the surface finish should be non-reflective to reduce glare and enhance visibility during operation.

When selecting welding fixture tables for your workshop, several critical factors must be taken into account to ensure optimal performance and efficiency. According to the American Welding Society, the right fixture table can increase productivity by up to 30%, making it a worthwhile investment. First, consider the material of the table; heavy-duty steel tables offer durability and stability, essential for precise welding tasks. Additionally, the surface finish should be non-reflective to reduce glare and enhance visibility during operation.

Tip: Always assess the weight capacity of the table to match your workload demands. Tables with adjustable heights can also provide ergonomic benefits, reducing strain during long welding sessions.

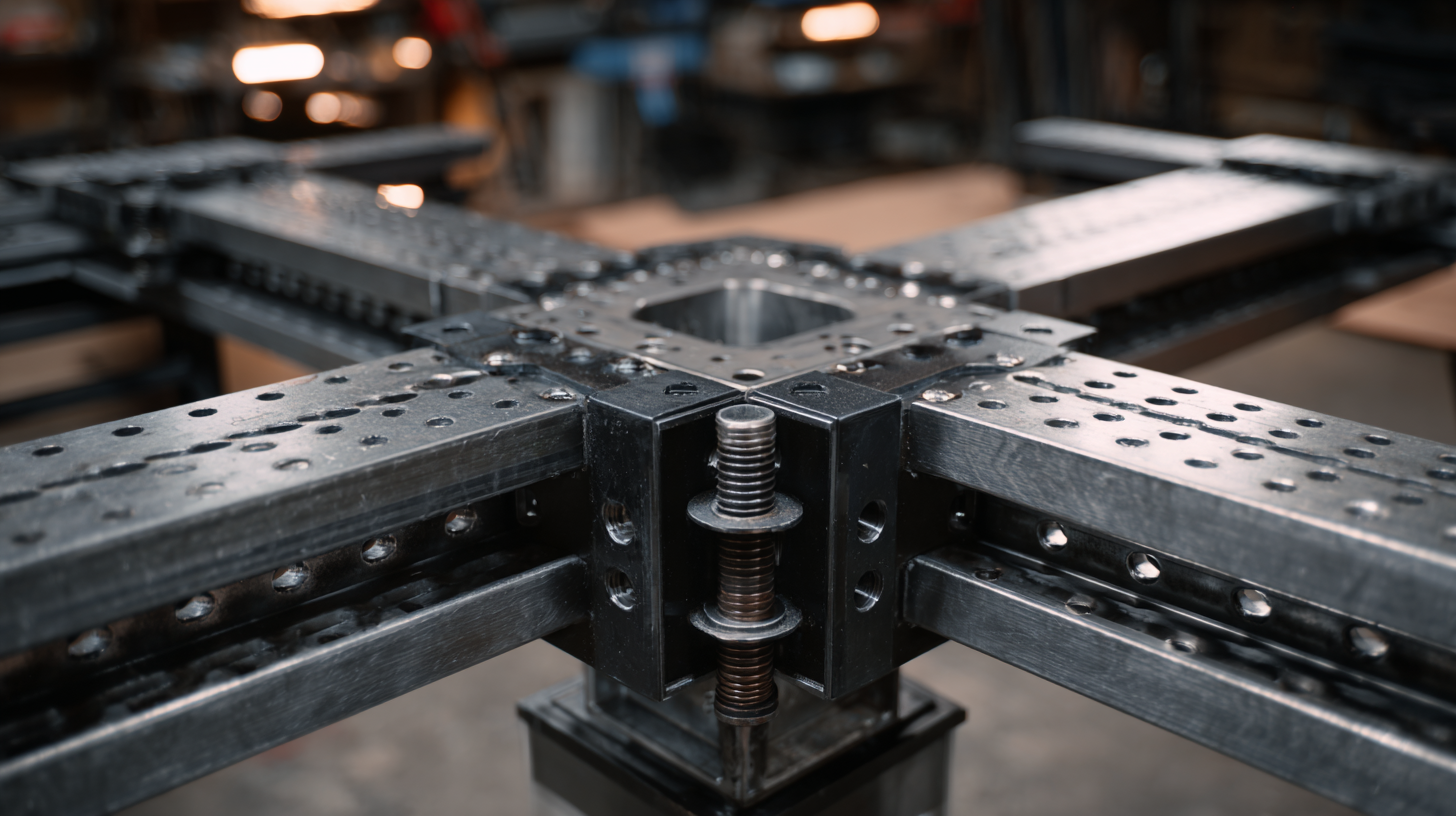

Another crucial factor is the table’s modularity and compatibility with various fixtures and clamps. The ability to customize your setup can streamline your workflow significantly. A survey by Welding Design & Fabrication revealed that 70% of fabricators prefer tables with adjustable work surfaces, enhancing their versatility for different projects.

Tip: Invest in tables that offer grid systems or T-slots for easy attachment of clamps and other tools. This flexibility can enhance productivity and help manage complex assemblies efficiently.

When selecting the best welding fixture tables for your workshop, it's essential to understand the various types available and their specific uses. There are primarily three types of welding fixture tables: flat tables, adjustable tables, and modular tables. Flat tables are ideal for general welding tasks and provide a stable surface for fabricating smaller parts. According to the Welding Equipment Manufacturers Association, these tables are widely used in small to medium-sized shops, accounting for approximately 45% of the market share.

Adjustable tables offer versatility for fabricators who require different heights or angles for various projects. These tables often come with integrated clamping systems, making them suitable for both industrial and custom welding applications. A recent industry report indicated that adjustable welding tables are gaining popularity, with a projected growth rate of 7.5% over the next five years due to their convenience and enhanced efficiency in production environments.

On the other hand, modular tables provide the ultimate flexibility, allowing users to reconfigure setups for different welding tasks. These tables are particularly valuable in larger manufacturing settings, where the ability to adapt the workspace to accommodate large components is crucial. According to a survey by the American Welding Society, about 30% of larger fabrication shops utilize modular tables, signifying their importance in boosting productivity and optimizing workflow.

This chart illustrates the popularity of different types of welding fixture tables used in workshops. Fixed tables lead the preferences, followed by rotating and adjustable tables, which are commonly favored for their versatility and functionality.

When setting up a welding workshop, one of the key considerations is assessing the size and space requirements for your welding fixture tables. According to industry reports, welding fixtures can vary significantly in size, often ranging from compact tables of 4x8 feet to larger configurations reaching up to 12x24 feet. The choice of table size will largely depend on the scope of projects you intend to undertake. Smaller workshops may benefit from modular fixtures that can be reconfigured easily, while larger spaces can accommodate expansive tables that facilitate multiple projects simultaneously.

Additionally, it is important to take into account the layout of your workshop. A well-planned space enhances workflow efficiency and safety. For instance, maintaining an operational area of at least 3 feet around each fixture table is crucial to ensure easy access and movement. With the growing trend of outdoor workshops seen in urban areas, where events meld creativity with functionality, welding enthusiasts can also explore portable options that allow them to maximize their workspace while enjoying the weather. This versatility not only improves productivity but also invites a new social dimension to welding as a craft.

When selecting welding fixture tables for your workshop, material choice plays a crucial role in performance and durability. Steel, often the preferred choice, offers significant benefits. For instance, mild steel with a tensile strength of approximately 370 MPa is robust enough to withstand heavy loads and high temperatures, which are common during welding processes. According to industry reports, around 60% of welding professionals favor steel tables for their ability to handle rigorous applications, ensuring consistent results.

Another material to consider is aluminum, which weighs less and provides excellent corrosion resistance. With a tensile strength ranging from 70 to 700 MPa depending on the alloy, aluminum tables are ideal for specific applications where mobility is essential. A recent survey indicated that about 30% of workshops prioritize lightweight solutions, which can enhance flexibility without compromising the quality of the welds. Furthermore, composite materials are gaining traction in the industry due to their resistance to deformation and longer lifespan, making them suitable for intricate welding tasks. Choosing the right material directly affects your workflow efficiency and the longevity of your fixture table.

When selecting welding fixture tables, budgeting for quality is a critical consideration. A well-built welding table can significantly enhance productivity and ensure precision in your projects. According to a report from the American Welding Society, nearly 50% of welding professionals cited inadequate work surfaces as a primary factor reducing their efficiency. This statistic underscores the importance of investing in a quality table that meets your workshop's specific needs.

The price range for welding tables can vary widely, typically between $300 and $3,000. Factors such as size, material, and additional features like adjustable heights or integrated clamps play a vital role in determining the cost. Investing at the higher end can offer benefits like increased durability and improved safety features. Industry experts recommend allocating about 5-10% of your overall workshop budget to your welding table. This investment not only enhances workflow but also decreases long-term costs by minimizing equipment wear and tear, which ultimately leads to better project outcomes.