In today's fast-paced manufacturing landscape, the significance of choosing the right engineering fixtures cannot be overstated. According to a report by MarketsandMarkets, the global market for manufacturing fixtures is projected to reach $12.3 billion by 2025, driven by the increasing demand for automation and precision in production processes. Engineering fixtures play a pivotal role in enhancing productivity, improving accuracy, and reducing lead times in manufacturing operations. Case studies from leading industries, such as aerospace and automotive, illustrate how investing in the right fixtures can lead to a remarkable increase in efficiency—often by as much as 30%. With the right engineering fixtures, manufacturers can not only ensure consistent product quality but also achieve substantial savings, making it essential to carefully evaluate and select the best solutions tailored to their specific needs.

When selecting engineering fixtures for your manufacturing needs, it is crucial to first understand your specific manufacturing requirements. A comprehensive analysis of your production processes allows you to determine the precise type of fixtures needed, optimizing efficiency and reducing costs. According to a report by Grand View Research, the global market for manufacturing fixtures is projected to reach USD 4.17 billion by 2025, highlighting the growing importance of tailored solutions in engineering design.

Tip: Start by conducting a thorough assessment of your existing workflows. Identify any bottlenecks or inefficiencies, and consider how custom fixtures could address these challenges. This proactive approach enables manufacturers to streamline operations, leading to a reduction in cycle times and increased productivity.

In addition to operational considerations, compatibility with existing equipment should also guide your fixture selection. A study from Statista reported that nearly 70% of manufacturers reported challenges related to equipment integration. Ensuring that your fixtures are designed to work seamlessly with current machinery is vital for maintaining production quality.

Tip: Collaborate with your engineering team to evaluate the compatibility of potential fixtures. Utilize computer-aided design (CAD) software to visualize integration possibilities, ensuring that your investment aligns with both short-term and long-term manufacturing goals.

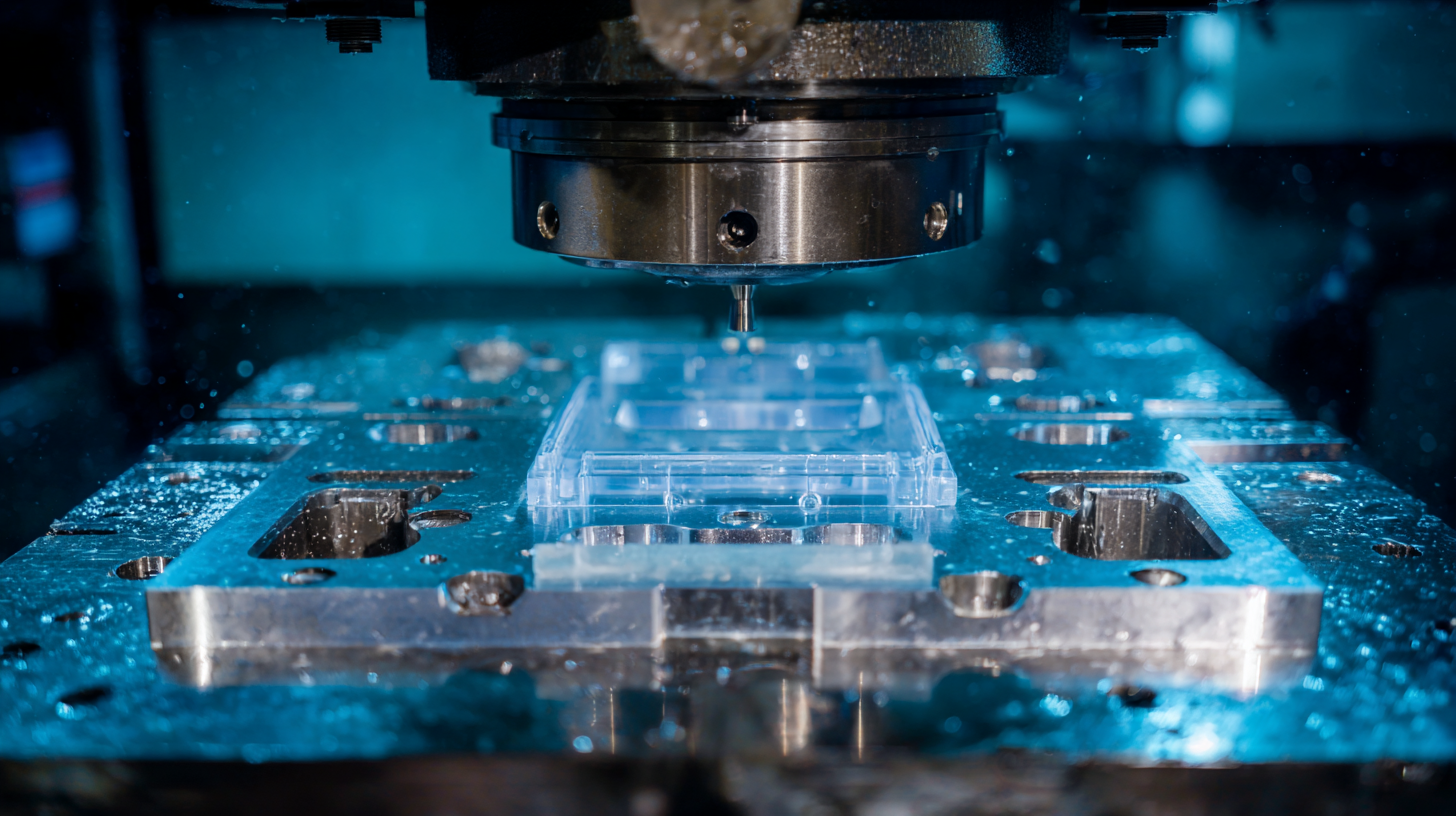

When selecting engineering fixtures for your manufacturing needs, several key factors come into play. First and foremost, the accuracy and precision required for your specific application cannot be overlooked. High-quality fixtures must ensure that components are held securely in place while allowing for precise machining or assembly. Consider the tolerances needed for your project and choose fixtures that provide the necessary stability and repeatability to meet those demands.

When selecting engineering fixtures for your manufacturing needs, several key factors come into play. First and foremost, the accuracy and precision required for your specific application cannot be overlooked. High-quality fixtures must ensure that components are held securely in place while allowing for precise machining or assembly. Consider the tolerances needed for your project and choose fixtures that provide the necessary stability and repeatability to meet those demands.

Another crucial aspect is the material of the fixtures. Engineering fixtures can be made from various materials, each offering different benefits. For example, aluminum fixtures are lightweight and easy to work with, while steel fixtures provide increased durability and strength for heavier components. Additionally, think about the environmental conditions in which the fixtures will be used; factors such as temperature fluctuations and exposure to corrosive materials should influence your material choices. Ultimately, selecting the right fixtures involves balancing these considerations with your manufacturing workflow to enhance efficiency and reduce production costs.

When selecting engineering fixtures for manufacturing, it’s crucial to conduct a comparative analysis of the various options available to ensure efficiency and cost-effectiveness. According to a report by Grand View Research, the global market for manufacturing fixtures is expected to reach $5.5 billion by 2027, growing at a CAGR of 4.5%. This growth underscores the importance of understanding the different types of fixtures, including dedicated, modular, and custom fixtures, each with distinct advantages and applications.

Dedicated fixtures offer precision for specific tasks, making them ideal for high-volume production runs. However, they may not be as flexible as modular fixtures, which allow for rapid adaptation to different parts and processes. Modular systems can reduce lead times significantly, as studies indicate they can improve production efficiency by up to 30%. On the other hand, custom fixtures, tailored to unique projects, provide the highest level of precision but typically involve higher initial costs and longer lead times. Understanding these key distinctions helps manufacturers select the right fixture type that aligns with their production goals and budget constraints.

When selecting engineering fixtures for manufacturing needs, cost-effectiveness and value assessment are paramount. The initial investment in fixtures can significantly impact a project’s overall budget, but it’s essential to evaluate the long-term benefits they offer. High-quality fixtures might come with a higher price tag, but their durability and reliability often lead to reduced maintenance costs and fewer production interruptions. This ultimately enhances productivity and ensures a smoother manufacturing process.

Additionally, it is crucial to consider the value derived from the fixtures in terms of their efficiency and versatility. Choosing fixtures that can accommodate various parts or processes can mitigate the need for multiple specialized units, leading to a more streamlined operation. Furthermore, assessing the potential return on investment (ROI) by analyzing production rates, waste reduction, and labor savings can help in making informed choices. By balancing upfront costs with long-term performance benefits, manufacturers can ensure they choose the best engineering fixtures that align with both budgetary constraints and operational goals.

This chart compares the cost-effectiveness and value assessment of different types of engineering fixtures used in manufacturing. The data represents the average costs in USD vs. the productivity value they provide.

When implementing engineering fixtures in production, it's crucial to align them with your specific manufacturing processes. Start by thoroughly analyzing your production requirements, including the types of materials you will work with and the complexity of the parts you intend to produce. This initial assessment guides you in selecting fixtures that enhance precision and efficiency. Utilizing modular fixtures can also provide the necessary versatility, allowing for easy adjustments and scalability as production demands change.

Another best practice is to involve your engineering and production teams in the selection and design process. Collaborative input helps ensure that the fixtures cater to real-world applications and can handle the tolerances and load conditions expected on the shop floor. Furthermore, implementing a feedback loop post-installation can offer insights into performance, allowing for continuous improvement and adjustments. Regular training for your operators on using the fixtures effectively is also essential to maximize productivity and minimize errors, ensuring a smoother integration into your workflow.

| Fixture Type | Material | Application | Key Features | Cost Estimate |

|---|---|---|---|---|

| Welding Fixtures | Steel | Automotive Parts | Adjustable, Durable, High Precision | $2,500 - $5,000 |

| Assembly Fixtures | Aluminum | Electronics | Lightweight, Easy to Handle | $1,000 - $3,000 |

| Machining Fixtures | Cast Iron | Heavy Machinery Parts | Stable, High Rigidity | $3,000 - $6,000 |

| Inspection Fixtures | Plastic | Quality Control | Lightweight, Portable | $500 - $1,500 |

| Automated Fixtures | Composite Materials | Mass Production | Programmable, Efficient | $10,000 - $30,000 |