In the fast-evolving landscape of manufacturing, selecting the appropriate welding fixture is crucial for optimizing productivity and ensuring high-quality outputs. According to a recent industry report published by the American Welding Society, nearly 70% of manufacturers cite the efficiency and precision of their welding processes as pivotal to their operational success.

With the global welding equipment market projected to reach $25 billion by 2025, the significance of choosing the right welding fixture becomes even more pronounced. This critical component not only influences the accuracy of welds but also impacts overall production efficiency and safety standards.

As industries face increasing demands for faster production times and higher quality, understanding how to effectively select the best welding fixture tailored to specific manufacturing needs is essential for staying competitive in today’s market.

When selecting the best welding fixture for your manufacturing needs, it is crucial to first understand the specific requirements of your welding process. According to a report by the American Welding Society, over 60% of production errors in welding are due to inadequate fixturing. This emphasizes the importance of alignment, stability, and repeatability in your welding operations. By thoroughly assessing your current welding techniques and identifying critical factors such as joint design, load capacity, and accessibility, you can make an informed decision when choosing a welding fixture.

**Tip 1:** Always evaluate the materials you will be working with. Different metals require distinct fixture designs; for instance, aluminum may expand differently than steel under heat, influencing fixture performance.

Additionally, consider the automation level of your welding process. Automated systems often necessitate more precise fixtures to accommodate robotic arms and lasers. A manufacturing report from SMED suggests that optimizing welding fixtures can reduce cycle times by up to 30%. Investing in high-precision fixtures could, therefore, lead to significant enhancements in productivity.

**Tip 2:** Regularly update and maintain your welding fixtures. Over time, wear and misalignment can lead to increased defects, so establishing a maintenance routine can prolong the life of your fixtures and ensure consistent output quality.

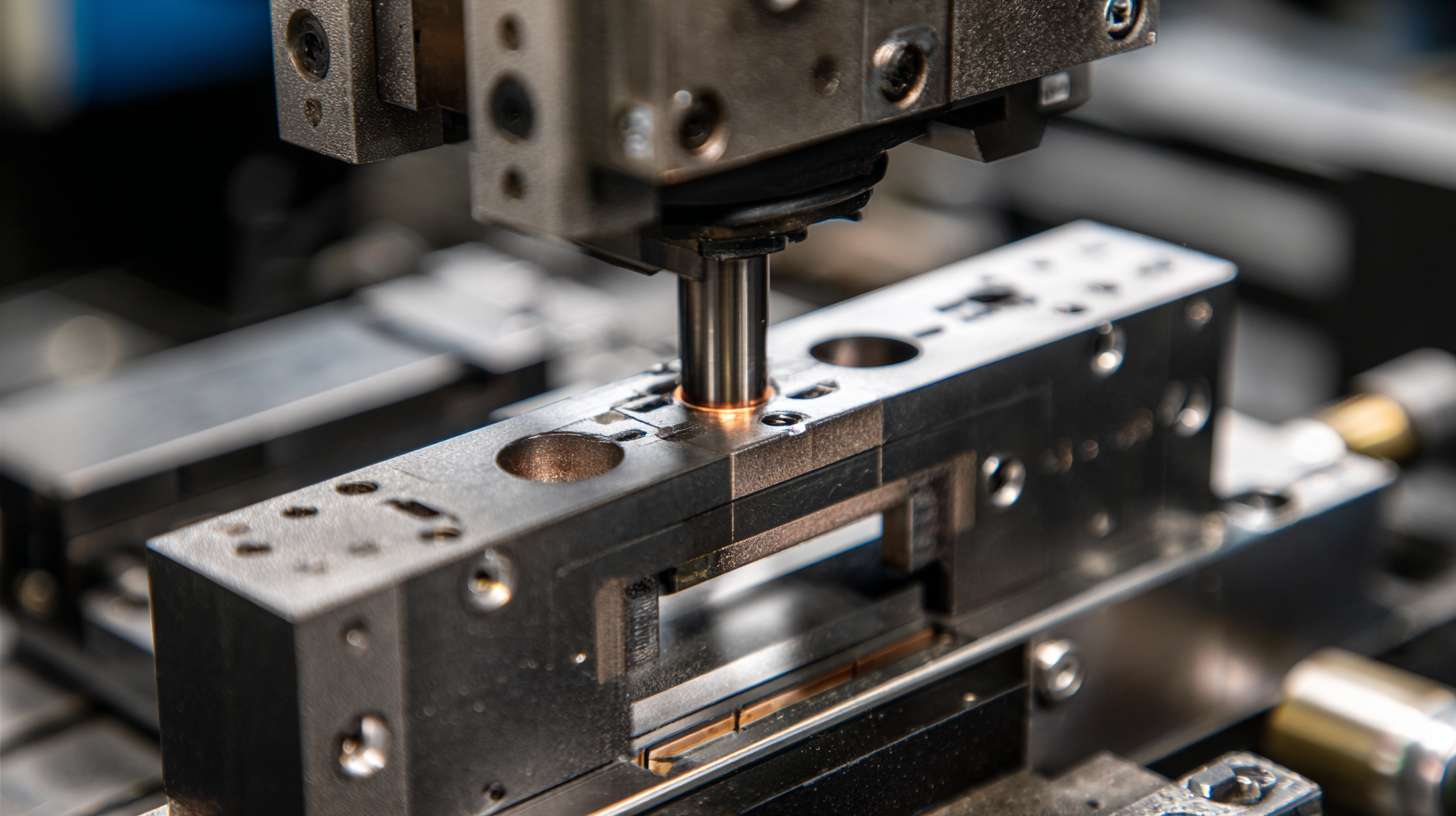

When selecting a welding fixture for your manufacturing needs, it's essential to identify key features that ensure optimal fixture performance. First and foremost, accuracy and repeatability are critical in any welding operation. A well-designed fixture should maintain tight tolerances to ensure that every weld is consistent, minimizing the risk of defects. Look for features such as adjustable clamps, which can help accommodate various workpieces while maintaining precise alignment.

Another important consideration is the material and construction of the fixture. A robust fixture made from high-quality materials can withstand the stresses of welding operations, prolonging its lifespan and reducing maintenance costs. Additionally, consider the fixture's adaptability. A versatile fixture allows for quick changes between different projects, increasing efficiency and productivity on the shop floor. Features like modular design or interchangeable components can significantly enhance the usability of your welding fixture, making it a more valuable investment for your manufacturing process.

| Feature | Importance Level | Description | Recommended Material |

|---|---|---|---|

| Material Selection | High | Choosing the right material affects durability and performance. | Steel or Aluminum |

| Adjustability | Medium | Fixtures should allow for adjustments to accommodate different sizes. | Cast Iron |

| Ease of Use | High | A user-friendly design increases efficiency and reduces errors. | N/A |

| Cooling Solutions | Medium | Incorporating cooling mechanisms can extend tool life. | Copper |

| Cost-Effectiveness | High | Consideration of initial investment vs long-term savings. | N/A |

When selecting the best welding fixture for manufacturing needs, evaluating material choices for durability and strength is crucial. The right material can significantly enhance the performance and lifespan of the fixtures. According to the latest industry reports, robust materials such as high-strength steels and advanced alloys are often preferred due to their impressive mechanical properties and resistance to wear. High-strength steel boasts an ultimate tensile strength exceeding 300 MPa, making it an ideal choice for fixtures subjected to high loads and repeated use.

Additionally, innovative materials like nylon, as explored by designers at Manchester Metropolitan University, are making waves in 3D printing applications, particularly in tubular textile structures. Their research indicates that selecting the appropriate nylon powder can lead to enhanced durability and flexibility in the final product. As the global demand for advanced materials continues to grow, projected market trends suggest that the construction and automotive sectors will increasingly adopt these materials for their fixtures, reinforcing the intersection of technology and material science in manufacturing processes. Reports indicate the concrete additives market is expected to grow from $22.9 billion in 2024 to $42.67 billion by 2031, highlighting the significance of material innovation in industry sustainability and efficiency.

When selecting the best welding fixture for your manufacturing requirements, it's essential to consider cost-effectiveness alongside your budget constraints. Start by evaluating the overall costs of different fixture types against your production volume and complexity of the welds. A more intricate fixture may have a higher initial cost but can lead to significant savings in time and labor during production, ultimately improving your bottom line. Analyzing the long-term benefits versus upfront expenses is crucial for making a sound investment.

When selecting the best welding fixture for your manufacturing requirements, it's essential to consider cost-effectiveness alongside your budget constraints. Start by evaluating the overall costs of different fixture types against your production volume and complexity of the welds. A more intricate fixture may have a higher initial cost but can lead to significant savings in time and labor during production, ultimately improving your bottom line. Analyzing the long-term benefits versus upfront expenses is crucial for making a sound investment.

Additionally, collaborating with your manufacturing team can provide valuable insights into how different fixtures impact workflow and efficiency. Seek fixtures that not only align with your budget but also enhance operational performance. Consider the durability and maintenance costs of the fixtures, as these factors can influence your total expenditure over time. By integrating cost assessments into your decision-making process, you can achieve a balance between affordability and functionality, ensuring that your welding fixtures deliver the best return on investment.

When selecting the best welding fixture for manufacturing needs, flexibility and customization options are paramount. As industries evolve, the demand for adaptable manufacturing solutions becomes critical. A comprehensive report indicates that the global headless CMS market is projected to grow significantly, reaching a valuation of $3.72596 billion by 2032, with a compound annual growth rate (CAGR) of 19.99%. This growth underscores the need for systems that can efficiently adapt to changing market trends and production processes.

China’s manufacturing sector is currently facing unprecedented challenges, which can resonate with the importance of flexibility in welding fixtures. As global demand slows and costs rise, manufacturers must consider solutions that allow for easy customization and scalability. Adapting welding fixtures to accommodate different product lines or evolving technologies can streamline production and reduce downtime. Given the projected growth in various tech sectors, companies that invest in flexible manufacturing solutions are likely to thrive amidst the shifting landscape. This foresight in choosing the right welding fixture could be the difference between stagnation and robust growth.