In the ever-evolving landscape of the automotive industry, ensuring the safety and reliability of vehicles has become paramount. One critical component in achieving this goal is the use of Car Checking Fixtures. These specialized tools are essential for the precise measurement and inspection of various automotive components, helping manufacturers maintain the highest standards of quality control. By integrating innovative technology and sophisticated design, Car Checking Fixtures not only streamline the production process but also significantly enhance the overall safety of the vehicles.

This article explores the pivotal role that these fixtures play in the automotive sector, underlining their importance in preventing defects, improving performance, and fostering consumer trust. As the industry continues to advance, the fundamental value of Car Checking Fixtures in promoting automotive safety cannot be overstated, highlighting the need for manufacturers to adopt best practices in their implementation and utilization.

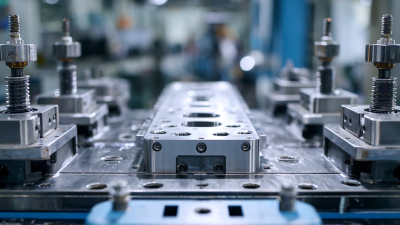

Car checking fixtures play a critical role in enhancing automotive safety by ensuring that each component of a vehicle meets stringent safety standards. As the automotive industry evolves, particularly with the rise of new energy vehicles and heightened regulatory demands, the importance of meticulous inspection processes cannot be overstated. These fixtures facilitate the automated and precise assessment of essential components, enabling manufacturers to identify potential safety issues before they reach the consumer market.

Car checking fixtures play a critical role in enhancing automotive safety by ensuring that each component of a vehicle meets stringent safety standards. As the automotive industry evolves, particularly with the rise of new energy vehicles and heightened regulatory demands, the importance of meticulous inspection processes cannot be overstated. These fixtures facilitate the automated and precise assessment of essential components, enabling manufacturers to identify potential safety issues before they reach the consumer market.

With the increasing complexity of vehicle systems, especially in electric vehicles, the need for effective testing and validation has become paramount. High-voltage components require specialized checking fixtures to conduct thorough assessments, ensuring that all parts function seamlessly together. The integration of advanced technologies in manufacturing, such as automation and machine learning, allows for more efficient inspections, ultimately contributing to higher safety standards in the automotive sector. These efforts not only protect consumers but also bolster the industry's commitment to safety and innovation in an ever-competitive landscape.

Precision measurement plays a pivotal role in vehicle inspection processes, ensuring that every component of a vehicle meets stringent safety standards. When automobiles are subjected to inspections, the accuracy of the measuring tools and procedures used directly impacts the reliability of the findings. This means that specialized car checking fixtures, designed for precise measurement, are essential in identifying potential safety hazards that may not be visible to the naked eye.

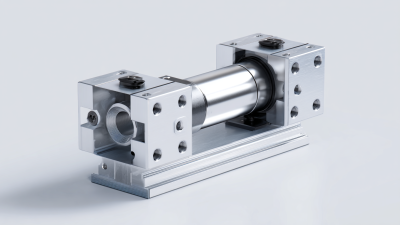

Incorporating advanced technology such as laser measurement systems and high-precision gauges, these fixtures facilitate a thorough examination of critical vehicle areas, including the alignment of wheels, suspension systems, and body structure. By providing exact measurements, automotive engineers can make informed decisions about necessary repairs or adjustments, thereby enhancing overall vehicle safety. In this way, precision measurement not only contributes to the structural integrity of the vehicle but also fosters a culture of safety within the automotive industry, ultimately protecting drivers and passengers alike.

This chart illustrates the correlation between regular vehicle inspections and overall automotive safety improvements over a year. The data highlights the number of safety checks conducted each month, reflecting their crucial role in maintaining vehicle performance and reliability.

Quality control in the automotive industry is a critical factor in reducing accident rates. According to recent industry statistics, vehicles that undergo rigorous quality checks experience significantly fewer malfunctions. For instance, reports indicate that cars with well-maintained checking fixtures result in a 30% drop in mechanical failures during operation. With increased attention to quality assurance, manufacturers can not only improve the reliability of their vehicles but also enhance overall road safety.

Tips for ensuring quality control include regularly scheduled maintenance of car checking fixtures and adopting a proactive approach to identifying potential mechanical issues. It is also beneficial for automotive companies to invest in advanced diagnostic tools that can detect even the slightest deviations from safety standards. By prioritizing these practices, manufacturers can effectively mitigate risks and contribute to a safer driving environment.

Moreover, continuous training for automotive technicians on quality control processes is essential. Keeping staff updated on best practices can lead to more accurate inspections and repairs. As a result, consumers can have greater confidence in the vehicles they drive, further contributing to the decline in automotive accident rates.

Implementing effective car checking fixtures is crucial for maintaining automotive safety. According to a report by the National Highway Traffic Safety Administration (NHTSA), vehicle defects were linked to approximately 22% of all traffic accidents in recent years. This underscores the necessity of thorough and regular inspections using specialized fixtures that can accurately identify potential issues before vehicles hit the road. By employing state-of-the-art checking fixtures that utilize advanced technology, automotive manufacturers and service providers can ensure a higher level of accuracy and reliability in vehicle safety checks.

Best practices in implementing car checking fixtures include routine calibration and maintenance to ensure their optimal performance. The Automotive Industry Action Group (AIAG) suggests that properly calibrated equipment can reduce inspection errors by up to 30%. Furthermore, integrating data analytics into the inspection process can enhance the ability to track defects over time, enabling manufacturers to address recurring issues proactively. A systematic approach to quality control not only improves vehicle safety but also contributes to higher customer satisfaction, as consumers can trust the reliability of their vehicles based on robust inspection practices.

As the automotive industry continues to evolve, so do the technologies that ensure vehicle safety. Innovations in checking technologies play a pivotal role in enhancing automotive safety, providing manufacturers and consumers with tools to identify potential risks before they manifest. Advanced diagnostics, AI-driven analytics, and real-time monitoring systems are revolutionizing how vehicles are assessed. These innovations not only improve the efficiency of safety checks but also enhance the overall reliability of vehicles on the road.

Tips for implementing these technologies include regularly updating software systems to ensure compatibility with the latest checking tools and conducting thorough training for personnel involved in the checking process. Regularly scheduled maintenance checks can also help in identifying any discrepancies before they escalate into significant issues.

Moreover, the integration of IoT devices in vehicles allows for continuous data collection and analysis, leading to more informed decision-making. By utilizing predictive maintenance models, automotive manufacturers can anticipate when safety checks are needed, reducing the likelihood of failures. This proactive approach not only enhances safety but also improves consumer confidence in automotive brands.