In the fast-paced world of manufacturing, efficiency and precision are paramount to meeting the ever-increasing demands of global markets. As China solidifies its reputation as a manufacturing powerhouse with a far-reaching export footprint, the optimization of production processes becomes essential. One of the most significant advancements in this arena is the use of Fixtures Jigs, which enhance both accuracy and productivity in manufacturing operations. These innovative tools not only streamline assembly and reduce setup times but also ensure a higher quality of output, making them indispensable for any production line. In this blog, we will explore the five unmatched benefits of using the best Fixtures Jigs tailored for your production needs, highlighting how they can contribute to fostering excellence in the competitive landscape of modern manufacturing.

When it comes to enhancing precision in production, using the best fixtures jigs can transform your manufacturing process. According to the 2022 Manufacturing Precision Metrics Report, companies that utilize precision fixtures have seen a productivity increase of over 30%. This enhanced precision not only improves the quality of the finished product but also minimizes waste and reduces the likelihood of costly production errors. With precise alignment and stability provided by these tools, manufacturers can consistently achieve tighter tolerances, which is especially crucial in industries like aerospace and automotive where reliability is paramount.

Tip: Regularly assess the condition of your jigs and fixtures to ensure they maintain their accuracy. Even small wear and tear can significantly impact production quality.

Moreover, precision fixtures jigs facilitate faster cycle times, allowing industries to meet tight deadlines without compromising quality. A study by the International Journal of Advanced Manufacturing Technology indicated that by incorporating high-quality jigs, production lines could reduce their cycle times by up to 25%. This improvement not only enhances operational efficiency but also promotes greater competitiveness in a market that increasingly demands agility and precision.

Tip: Consider investing in adjustable jigs that can accommodate variations in your production line, enhancing flexibility while maintaining accuracy.

Efficient jigs are revolutionizing manufacturing processes, particularly in reducing time and labor costs. By utilizing high-quality fixtures and jigs, production lines can achieve higher accuracy and consistency, which translates to less waste and rework. This accelerated workflow not only increases output but also minimizes the labor hours required for assembly tasks. When every second counts in production, investing in the best jigs is a smart decision that pays off in the long run.

Tip: One effective strategy is to routinely assess your current jigs for wear and suitability. Upgrading to more precise fixtures can lead to significant time savings, as they streamline the setup process and reduce the chance of errors. Additionally, implementing ergonomic designs can improve worker comfort and efficiency, further decreasing labor costs.

Another key tactic is to train your workforce on the optimal use of jigs and fixtures. Well-informed employees can better utilize these tools, resulting in smoother operations. Consider holding workshops to demonstrate best practices and encourage feedback, fostering a culture of continuous improvement and innovation on the production floor.

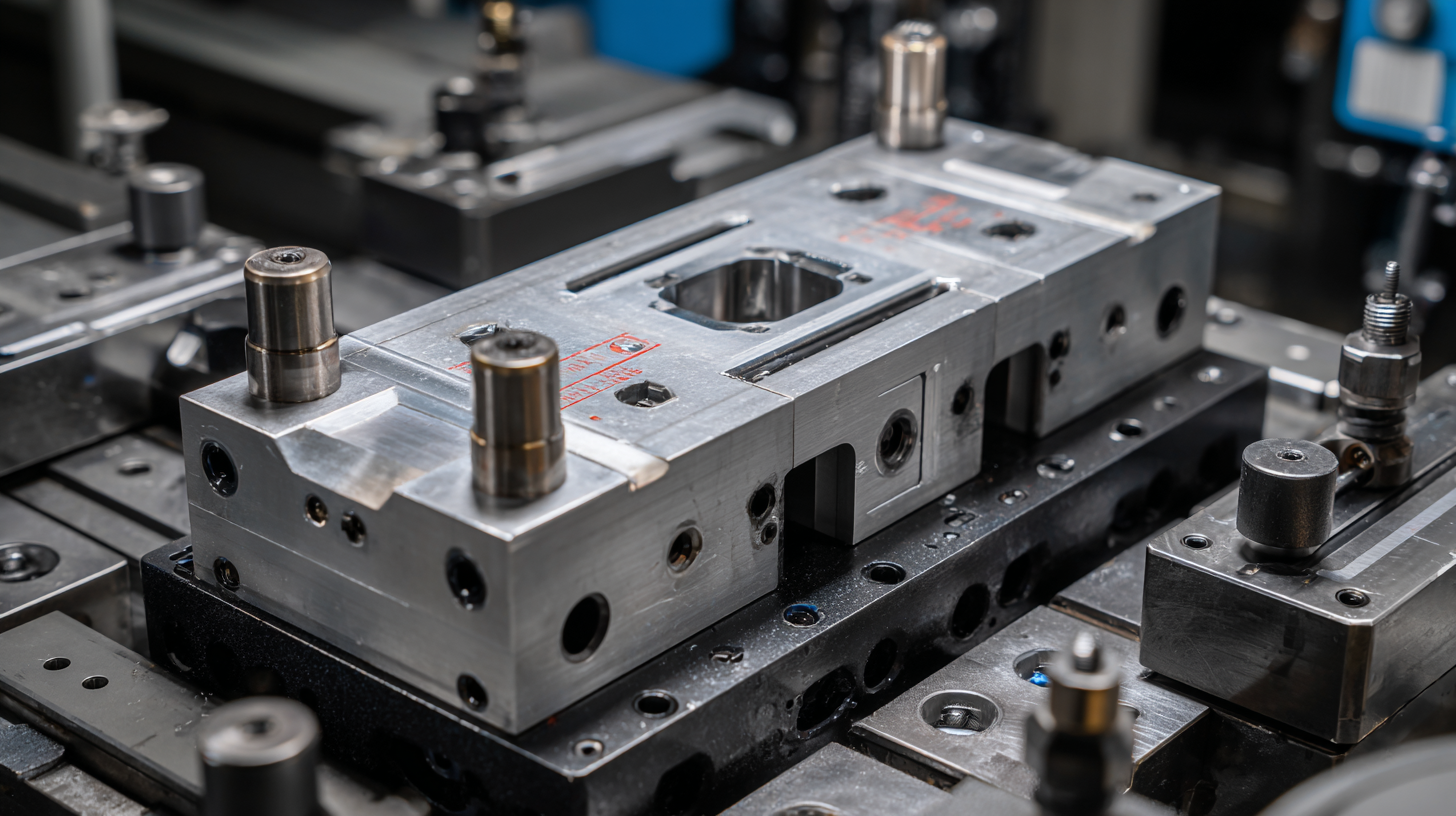

Using jigs and fixtures in manufacturing processes significantly enhances product quality and consistency. These tools are designed to hold and support the workpieces in a precise position, allowing operators to focus on their craft without distractions. By ensuring that each component is accurately aligned, jigs and fixtures help reduce the variability that can arise from manual assembly processes. This uniformity is critical in industries where even slight discrepancies can lead to defects or malfunctions, ultimately affecting customer satisfaction and trust.

Using jigs and fixtures in manufacturing processes significantly enhances product quality and consistency. These tools are designed to hold and support the workpieces in a precise position, allowing operators to focus on their craft without distractions. By ensuring that each component is accurately aligned, jigs and fixtures help reduce the variability that can arise from manual assembly processes. This uniformity is critical in industries where even slight discrepancies can lead to defects or malfunctions, ultimately affecting customer satisfaction and trust.

Furthermore, the implementation of quality jigs and fixtures leads to efficient production cycles. With enhanced precision, workers can complete tasks more quickly and with fewer errors, resulting in a streamlined workflow. This efficiency not only saves time but also reduces material waste, as fewer defective parts are produced. As a result, manufacturers can maintain competitive pricing while delivering high-quality products, reinforcing their brand reputation. Investing in the best fixtures and jigs not only elevates product quality but also fosters a culture of continuous improvement within production teams.

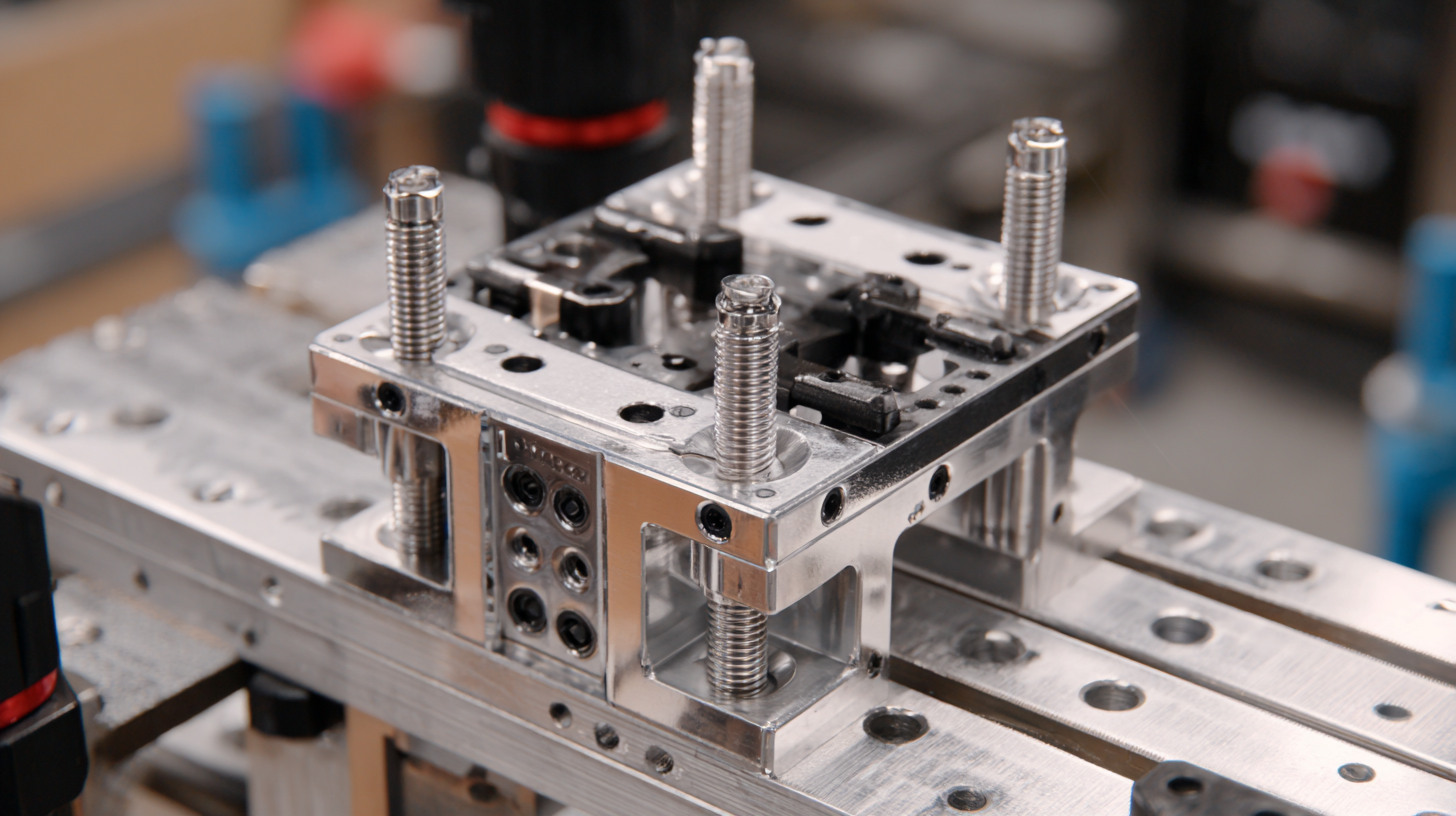

In today's fast-paced manufacturing environment, flexibility and customization are essential for meeting diverse production needs. Utilizing the best fixtures jigs allows companies to adapt their processes with remarkable ease. These jigs are designed to accommodate various shapes, sizes, and types of workpieces, enabling manufacturers to switch between different products without the need for extensive retooling. This adaptability not only streamlines workflows but also increases the overall efficiency of production lines.

Moreover, the customizability of jigs enhances precision and consistency in operations. Manufacturers can modify their jigs to suit specific tasks, ensuring that each component is produced to exact specifications. This level of customization reduces waste and minimizes errors, which are critical factors in maintaining product quality. As a result, businesses can respond more swiftly to market demands, innovate their product offerings, and ultimately gain a competitive edge in their industry. By harnessing the power of jigs, production facilities can effectively manage a wide range of manufacturing challenges while optimizing their operational capabilities.

In today's manufacturing landscape, enhancing safety standards is imperative for operational success. Advanced fixture solutions play a crucial role in mitigating risks associated with production processes. According to a report by the National Institute for Occupational Safety and Health (NIOSH), implementing effective safety measures can reduce workplace injuries by up to 40%. By utilizing the best fixtures and jigs, companies can create a more stable and secure working environment. These fixtures allow for precise alignment and support, minimizing the likelihood of accidents caused by equipment instability or human error.

To elevate your safety standards, consider these tips: first, ensure that all fixtures are routinely inspected and maintained to prevent equipment failure. Regular audits can identify potential hazards before they lead to incidents. Second, incorporate ergonomic designs in your jigs to reduce physical strain on workers. A study published in the Journal of Safety Research found that ergonomic improvements led to a 30% decrease in musculoskeletal injuries in manufacturing settings. Lastly, provide proper training on the use of fixtures to instill a safety-first mindset among employees, ensuring they are aware of the correct protocols when operating machinery.

By prioritizing advanced fixture solutions, organizations not only enhance their safety standards but also foster a culture of care and responsibility in the workplace.

| Benefit | Description | Impact on Safety |

|---|---|---|

| Precision Alignment | Advanced jigs ensure that components are precisely aligned during assembly, reducing errors. | Minimized risk of accidents due to misalignment, enhancing overall safety. |

| Increased Efficiency | Streamlined production processes that speed up assembly times. | Fewer rushed actions reduce the likelihood of workplace injuries. |

| Reduced Waste | Precision fixtures lead to less material waste, promoting sustainability. | Less waste means fewer handling operations, lowering the risk of related accidents. |

| Enhanced Worker Comfort | Ergonomically designed fixtures reduce strain and improve comfort during tasks. | Improved worker comfort directly correlates to lower injury rates. |

| Consistent Quality Control | Fixtures ensure that every product meets predefined quality standards. | Higher quality standards reduce the need for rework, lessening exposure to hazardous conditions. |